The dynamic electronic floor scale completes the measurement of animals and displays the data to the operation department. The computer automatically compares the displayed measurement data with the pre-set standard weight value and upper and lower limit values, and distinguishes and sorts genuine products, overweight products and underweight products. The entire process does not disrupt the normal operation of the animal line and requires no manual intervention.

020-34563445

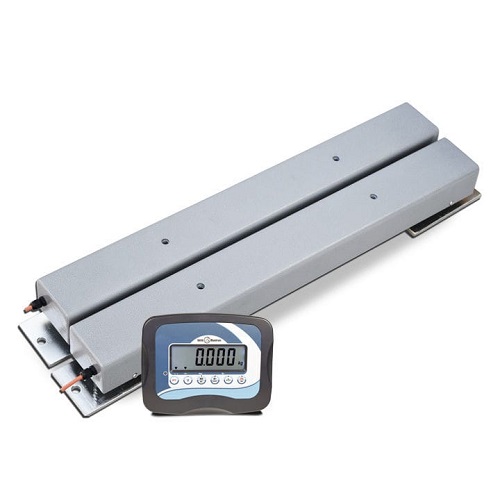

020-34563445The dynamic electronic floor scale mainly consists of an animal introduction scale platform, a barcode reader, an animal dynamic weighing device, photoelectric switches, a pneumatic solenoid valve rejection device, an audible and visual alarm, a rejection storage platform and a tablet computer, etc. The animals to be tested are introduced into the dynamic weighing device through the scale platform for underweight detection. Finally, based on the detection and judgment results, when overweight or underweight occurs, the system software automatically triggers an electrical signal through the serial port of the tablet computer, connecting the intermediate relay, thereby enabling the pneumatic solenoid valve and the sound and light alarm to work.

Animals are led into the Electronic scale at neat and equal intervals through the fence. When they pass the photoelectric sensor located at the front end of the electronic scale, the weight detection begins to measure the living creature. During the process of animals passing through the electronic floor scale for measurement, the weighing module completes the measurement of the animals and displays the data to the operation department. The computer automatically compares the displayed measurement data with the pre-set standard weight value and upper and lower limit values, and distinguishes and sorts genuine, overweight and underweight products. The entire process does not disrupt the normal operation of the animal line and requires no manual intervention.

When the animal moves from the fence to the scale platform, the weight on the scale platform reaches the weight trigger point. After passing through the set invalid AD number, the weighing instrument performs digital filtering on the collected valid AD number. When the valid AD number reaches the set value, it is averaged again to calculate the weight of the object being tested. The instrument compares this weight with the set standard value to determine which zone the object being tested belongs to and whether it should be removed. When the item to be inspected leaves the scale platform, the automatic zero-point tracking starts to work until the next item enters the scale platform.

Specification parameters

Range specification: 1t to 3t

Accuracy grade: (Ⅲ) grade

Graduation values: 0.5kg, 1kg

Low-value alarm Settings: Users can customize the Settings

Rated overload capacity: 130%F•S

Safety factor: 200%F•S

Distance between the scale body and the instrument: ≥30 meters

Working power supply: 220V/50HZ

The operating temperature range of the load cell is -30℃ to 80℃

Scale body external dimensions: 1200×800×240 (mm)