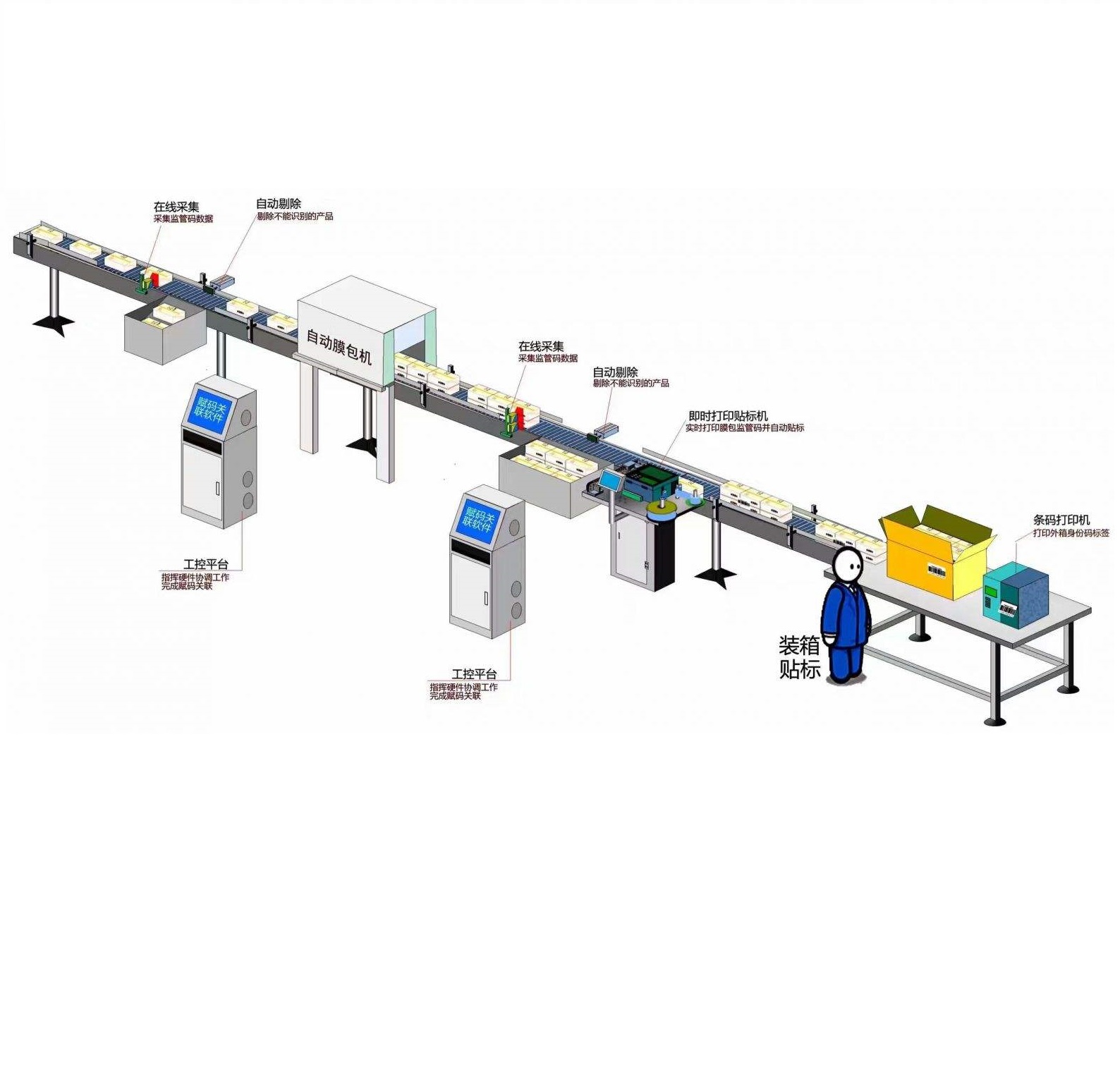

The core part of the coding weighing system, data acquisition and data association, is constructed according to the principle of finite automatic state machine, using the post-association mode, which can ensure that the product supervision code of weighing is completely consistent with the associated data uploaded to the electronic supervision network. According to the site and environment of each product production line, as well as the process and operation requirements of packaging and weighing, the collection and association of the supervision code of the products in the network, the mixed mode of automatic collection and manual collection (referred to as the automatic line mode).

020-34563445

020-34563445The coded Weighing system transmits the source information such as product production, weighing and quality to the supervision network database through the supervision code. The circulation enterprises check and accept the incoming goods through the supervision code and transmit the incoming goods information to the supervision network database. When selling, they transmit the sales information to the supervision network database. These data information can be used for consumers to inquire about authenticity and quality, for the government to carry out law enforcement and anti-counterfeiting, quality traceability and product recall management, and for enterprises to understand the market supply and demand, channel sales and fake information.

In order to realize the supervision of drugs, the coded weighing system needs to control the packaging coding of drugs (that is, the supervision code), and mark the supervision code on the outside of the packaging in the form of bar code, which can be read by scanning or naked eyes. According to the production plan formulated by the quality supervision department, the supervision code is applied for issuance on the product monitoring information network, and the supervision code is related to the products produced; Before production, the supervision code is introduced into the coding system through the data interface (that is, the supervision code coding system of weighing production line). In the process of production and packaging, the coding system codes several layers of packaging of each product, and associates the bar code relations of different layers of packaging through scanning and stores them in the database. The system sends the supervision code related data to the product monitoring information network system through the data interface according to the preset rules or artificially determined time points. After the supervision code is activated, it can be used when the product enters the circulation or use process.

The coded weighing system imports the original supervision code through the data interface with the monitoring information network system, and uploads the related supervision code to the monitoring information network system; Internal contact with scanning system, display screen, bar code printing system, labeling system, etc. Through the interface, it is transmitted to the background of the coding system through field data collection, and after the background logic processing, the information is fed back to the field to guide the operators how to carry out the next operation. If it is an automatic production line, it can guide the automatic equipment to carry out automatic production processing through the data interface.

The supervision code is the identification given to each product by the China government for electronic supervision of products. The supervision code of each product is unique, that is, "one code per product", which is like the ID card of a commodity.

At present, the supervision code has been upgraded from 16 digits to 20 digits. After the enterprise accurately registers the commodity code of its products, the supervision code can establish the corresponding relationship with the commodity code and complete the settlement and pricing function in the retail field.

Production enterprises transmit the source information of products such as production and quality to the supervision network database through the supervision code, while circulation enterprises conduct incoming inspection and acceptance through the supervision code and transmit the incoming information to the supervision network database. When selling, they transmit the sales information to the supervision network database. These data information can be used for consumers to inquire about authenticity and quality, for the government to carry out law enforcement and anti-counterfeiting, quality traceability and product recall management, and for enterprises to understand market supply and demand, channel sales and fake information.

The coded weighing system supports a variety of data sources, including calling external file database (text format), automatically generating data by software, collecting equipment data, serial weighing instrument, ERP data, manually entered data, etc. It controls the coded equipment to spray code, automatically records the sprayed code data, and realizes the uniqueness of spraying code. This software includes the following two versions: single-machine version and multi-machine version.

The specific functions are as follows:

1. Support the customization of laser coding information.

2, the external information code import

3, 10, 16, 24, 32, etc. The definition of serial number with arbitrary length in arbitrary decimal system.

4. Support two-dimensional code and one-dimensional code.

5. Coding equipment that supports various brands of equipment.

6. Support simultaneous management and control of any number of any devices.

7. Automatic data information generation

8, automatic data information upload

9. Automatic breakpoint recording

10. Template Save Management

11. Support serial code, encryption code, random code, set code and user-defined code.

12. Other user-defined functions