The Read the code weighing system realizes the automatic control of the whole system through the electronic scale, the weight is picked up through the pressure weighing module, and the weight signal is picked up for the transmission process and control requirements, including control scanning, coding equipment, printing equipment and other linkage work.

020-34563445

020-34563445The code reading and Weighing system is established in the factory according to the requirements of the enterprise, including automatic online labeling, automatic online data collection, and automatic association of the relationship between products and cartons, as well as the association between cartons and pallets. The product data collected, generated and associated during the production process on the automatic line will be stored in the server.

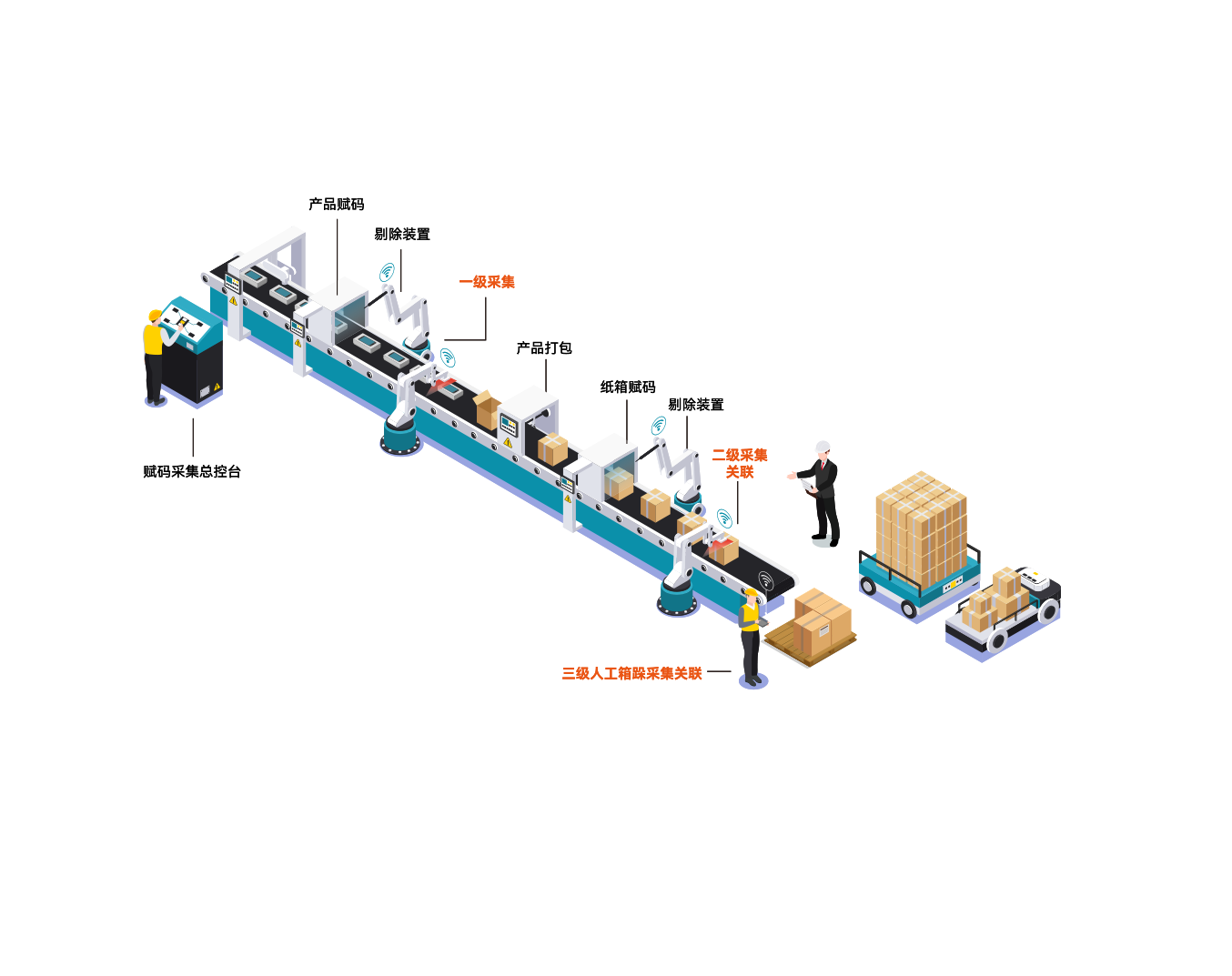

The production control server installed on the fully automatic production line is equipped with the "Production Line Collection, Coding and Association Control System Software" to achieve the interlinked control of related software and hardware in the data collection, online coding and online association system, collect product codes, generate box codes and pallet codes and associate the data.

Production line collection, coding and associated weighing system: A control software installed on the industrial control computer on the production line, which controls the coordinated operation of scanning, coding equipment, printing equipment, etc.

It is used to store the coding data of all production lines. After the production tasks of each production line are completed, users upload the coding data to the server, and the server uniformly queries and maintains the coding data of all products. On the server, all box codes and pallet codes associated with the product code can be queried, and the three-level codes can be mutually queried. The associated data can be exported in "EXCEL" format.

Labels and digital descriptions

According to the enterprise's requirements, it is necessary to design a one-code-per-item for the small packaging of the product: Users use laser coding. Since the product packaging is plastic, it is necessary to test the coding effect to ensure the reading rate of the QR code. When reading the QR code on the plastic packaging, the flatness of the QR code area needs to be considered.

Design description for carton labels: Contents of carton labels and large bag packaging labels: product name, specification, quantity, production date, production batch number, QR code, etc. Label size: 40*80

The label content includes: associating the product QR code with the QR code of the carton packaging to establish the relationship between the parent code and the child code (for example, establishing a relationship of 1 parent code and 20 child codes as instructed). The carton code is associated with the pallet code to achieve three-level code association. The number of parent-child associations for the first and second-level codes can be set.

Design description for pallet labels: Content of pallet labels: product name, specification, quantity, production date, production batch number, QR code; Label size: 40*80 The carton code is associated with the pallet code to achieve the association of two and three-level codes. The number of parent-child associations for secondary and tertiary codes can be set.

Specific process description

Product A is successively placed onto the product transmission and weighing system production line (depending on the situation, it can be combined with the production line).

The fixed code reader B reads the packaging bag code of the product. The read code is stored in the industrial control computer on the production line. If the reading fails, it notifies the control system to remove it.

When the number of QR codes of the products read meets the quantity of one box, the coding system will generate and print a box code to associate it with the product code. The box code and all the product codes inside the box form a one-to-many relationship and are stored in the database. The online labeling machine adheres the labels to the carton packaging.

On the production line, fixed code readers are used to read the QR codes on cartons or large bags. When the number of QR codes read reaches one pallet or the control system informs the coding system to complete the pallet stacking quantity, a pallet code is generated and the pallet is automatically pasted onto it. If the code reading fails, the carton or large bag packaging will be removed.

The e-code reader needs to transmit the QR code data read each time to the industrial control computer, which compares the encoded information to see if it meets the requirements and rules.