On-line laser coding and weighing is to put the marked object on the platform of electronic scale, and the laser is concentrated on the surface of the marked object with high energy density. By burning and etching, the substances on the surface of the marked object are vaporized, and by controlling the effective displacement of the laser beam, patterns or characters can be accurately burned.

020-34563445

020-34563445It has a mature hardware integrated application data weighing management system, and a cloud service platform that serves

Technical advantages:

1. The Weighing system of the online laser coding machine gives each item an "ID card", and consumers can query the production date, shelf life and other contents of the product through the QR code, which can be traced back to the production and circulation of the product.

2. The online laser coded weighing system is committed to providing product quality and safety management and brand protection solutions for different industries by using mobile Internet and big data analysis technology.

3, to prevent online and offline goods, to maintain the stability of the enterprise target market;

4. Greatly reduce the inventory risk of enterprises and realize on-demand production;

5. This system can also automatically count data according to customers' inquiries, help enterprises understand the market situation and consumers' situation, realize accurate marketing and improve product sales.

Application field:

Two-dimensional code label design applies advanced two-dimensional code identification technology to commodity labels to ensure that each genuine product obtains its own unique identity card in the production process, and intercepts the fraudulent and fake sales of bad businesses from the source of production; Consumers can verify the authenticity of goods and trace the origin by scanning the code on their mobile phones. Brand enterprises realize the online and offline dual commodity information traceability system through the "easy traceability code" scheme, and effectively solve the shortcomings of online and offline counterfeit control by using the perfect data record of the enterprise-specific security traceability cloud platform and its active anti-counterfeiting mechanism.

Through the security traceability QR code of each product, it not only brings consumers a brand-new experience of QR code anti-counterfeiting and authenticity verification, but also realizes value-added functions such as brand marketing, brand interaction, product promotion, promotion and publicity, channel anti-channeling, membership points, etc., and achieves good marketing effect for enterprises at low cost.

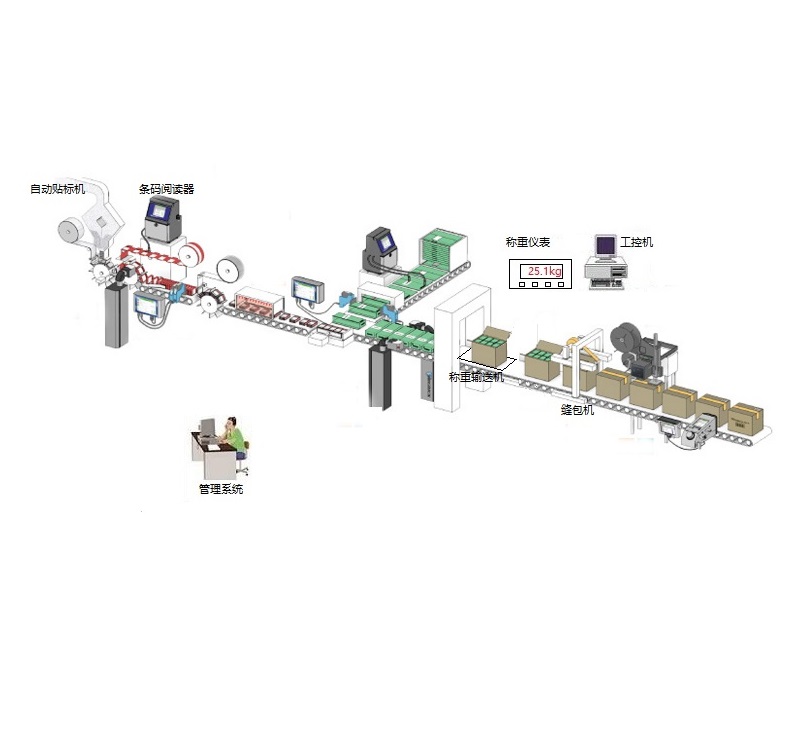

On-line laser coding and weighing system uses a laser marking machine (laser coding machine) to print a two-dimensional code for a single product on the packaging line of the production line. Through the control of on-site software, after printing a single product with a specified number of specifications (for example, 4 sets per box), it enters the weighing and weighing system, and then the bar code printer automatically prints the box code label, which is pasted when packing to form the relevant data of this box.

When the weighing system of laser dynamic coding and marking machine is packing, an industrial fixed collector is placed at the back end of the box sealing machine to scan and collect the bar codes after sealing. After scanning the bar codes of the specified number of boxes (for example, 75 boxes per tray), the bar code printer will automatically print the label of the tray and paste it at the designated position to form the relevant data of this tray.

The control system adopts color image display and "touch screen computer integrated workstation" to control respectively. And networking by means of communication, realizing the coordination of data acquisition, processing and feedback control. Achieve reasonable, timely, accurate and perfect automatic control of the whole production process.

The industrial computer adopts modularized real-time monitoring instrument hardware, and uses the powerful function of programmable logic controller (PLC) to realize full-automatic control, "monitoring of weighing and metering system", "automatic control of stacking unit", "recording and saving production data" and "networking with upper computer 485 or TCPIP communication and data transmission".

Action flow of laser dynamic coding and assigning machine: send the whole machine to the conveying line → laser marking machine prints two-dimensional code → automatic code reading → automatic elimination of code reading failure → automatic placing of manipulator in the packing box → weighing and measuring of weighing conveyor → printing of labels by industrial printer → manual labeling with normal weight (handling abnormal conditions manually with abnormal weight) → recording and saving data of scanning gun → automatic placing of manipulator in the tray → wireless handheld terminal verifying product warehousing → moving and inserting forklift into the tray.

The realization method of code Measurement system association of laser on-line coding and assigning machine

1. On-line laser inkjet printer weighing system production line is equipped with on-site industrial control, loading industrial control computer, on-site coding related software, PLC controller, two-dimensional code identification system, weighing conveyor, handheld wireless terminal, board card, etc., which are integrated into one. Coordinate the programmed actions of each part of hardware, and the distribution, correlation and arrangement of field data.

2. On-line laser marking machine metering system A laser marking machine is installed in the front of the packaging line of the production line, and the single unit on the assembly line is printed with anti-channeling code, which is generated by software encryption.

3. The metering system of the online laser code printer is equipped with a chain clamping device after the laser code spraying is completed, so that the products in each box can be separated by a certain distance to ensure the accuracy of data association.

4. The weighing system of online laser code printer is equipped with a bar code printer to print the bar code of each box after the laser code spraying is completed, which forms an association with a single machine at this time. Printed labels are placed on every specified quantity of products.

5. The manual packaging of the weighing system of the online laser inkjet printer will be carried out in groups, and each group will package each box of products. When it is placed in the assembly line again, it should be placed in sequence, and each box should be kept at a certain distance. Products damaged in the packaging process will be replaced or centralized.

6. When the products of the weighing system of the online laser marking machine are packed, the attached bar code label of the outer box is pasted to the designated position, and the industrial fixed collector is placed at the back end of the sealing machine, and the bar codes are scanned and collected in turn. The customer display screen at the scene will show the number of full pallets and the current scanned and collected quantity.

7. On-line laser capping machine weighing system When the bar codes of the specified specifications and quantities are scanned every time, the bar code printer automatically prints the label of the tray and pastes it at the designated position to form the relevant data of this tray. Export the related data of each batch and upload it to