Intelligent warehousing weighing system application technology reasonable use of the workshop's existing space, the use of space utilization is also part of the cost savings, combined with including RFID tags, fixed read-write, antennae, hand-held terminals, open weighing management channel. Choose according to the actual site requirements. Realize the integrated information weighing management process from printing orders, picking, scanning packages, orders for shipment, as well as redeployment and sorting, return to the factory shipment and other processes for data transmission and reading. Realize accurate in and out of the warehouse, quantity inventory management, RFID tags and read-write mutual application makes all automation complete.

020-34563445

020-34563445Traditional warehouse management generally relies on a non-automatic, paper-based RFTD warehouse Weighing system to record and track the incoming and outgoing goods, and the internal management of the warehouse is completely implemented manually, so the efficiency of warehouse management is extremely low and the size of the warehouse that can be managed is also very small. With the popularization of computer application, the warehouse management data of most enterprises have begun to be managed by computer data RFTD warehouse weighing system, but the data is still collected and statistically sorted by means of paper recording first and then manually entering into the computer. This not only causes a lot of waste of human resources, but also causes slow data entry and low accuracy due to human factors.

With the continuous development of enterprise scale, the number of materials managed by warehouse is increasing, the frequency of warehousing is increasing sharply, and the warehouse management op

The warehouse management RFTD warehouse weighing system based on radio frequency identification (abbreviated as RFID) introduces RFID technology into the existing warehouse management, and automatically collects the data of each operation link, such as warehouse arrival inspection, warehousing, warehousing, allocation, warehouse transfer and inventory counting, so as to ensure the speed and accuracy of data input in each link of warehouse management, ensure that enterprises can grasp the real data of inventory in time and accurately, and reasonably maintain and control enterprise inventory. Through scientific coding, it is also convenient to manage the batch and shelf life of items. Using the location management function of RFTD warehouse weighing system, we can know the current location of all inventory materials in time, which is conducive to improving the efficiency of warehouse management.

Third, the architecture of RFTD warehouse weighing system

A. design principles of a.RFTD warehouse weighing system

This scheme strictly follows the technical specifications involved in this project. Maximize the use of the most advanced technology of existing computers. Following the principles of real-time, integrity, stability, advancement and expansibility, the design scheme of RFTD warehouse weighing system with economic rationality and resource optimization is established.

(1) Real-time: This RFTD warehouse weighing system adopts the most advanced high-speed wireless network technology at present, which makes all the planning, operation, scheduling, control and management of the warehouse real-time, greatly improving the efficiency of the existing equipment and personnel in the warehouse and realizing the maximum benefit of logistics management.

(2) Integrity: This RFTD warehouse weighing system involves wireless handheld devices, wireless receiving devices, database foreground and background database servers. Although they are physically separated from each other, they are all supported by their own RFTD warehouse weighing system. In order to make each part work in a unified and coordinated way, it is necessary to ensure the overall consistency between them when designing.

(3) Stability: This RFTD warehouse weighing system is a production information RFTD warehouse weighing system serving warehouse management and field operation. Therefore, in the design of RFTD warehouse weighing system, an error analysis module is added to check all possible errors. In addition, the efficiency and stability of the RFTD warehouse weighing system are optimized in the design, so that the RFTD warehouse weighing system can ensure the stability while ensuring the speed. Through the above measures, the operation of the RFTD warehouse weighing system will not be affected when there are human errors or some random errors in the RFTD warehouse weighing system.

(4) Advanced: This RFTD warehousing and weighing system is an intelligent RFTD warehousing and weighing system integrating computer software and hardware technology, wireless network technology, internet technology, bar code automatic identification technology and database technology. The e-commerce sub-RFTD warehouse weighing system of this RFTD warehouse weighing system adopts the most popular computer three-tier structure system in the industry, adopts Java language and provides XML interface.

(5) Extensibility and maintainability: According to the principle of software engineering, the maintenance of RFTD warehouse weighing system accounts for the largest proportion in the whole software life cycle. Therefore, improving the scalability and maintainability of RFTD warehouse weighing system is a necessary means to improve the performance of this RFTD warehouse weighing system. This RFTD warehouse weighing system adopts a structured and modular structure, which can modify a module and add new functions as needed to make it have good maintainability. The RFTD warehouse weighing system also has interfaces with other sub-RFTD warehouse weighing systems, which makes this RFTD warehouse weighing system have good scalability.

B. Main functions of b.RFTD warehouse weighing system

(1) automatically and accurately update all kinds of information;

When the goods are in and out of the warehouse and need to be updated, the warehouse can be updated only by repairing the corresponding data through the handheld terminal; Or by querying the time database, we can find the goods of the corresponding model and update the data.

(2) Inquiring and tracking cargo information;

Log in to the software terminal of RFTD warehouse weighing system, search the specific information of the goods to be inquired, and transmit the searched information to the handheld terminal, so that the signboard can be easily found and the goods can be tracked;

(3) Location query, dynamic allocation of locations, random storage, so as to maximize the use of storage space;

Log in to the software terminal of RFTD warehouse weighing system, inquire about the location information, and realize the dynamic distribution of goods according to the storage space information of the location, so as to maximize the use of storage space.

(4) Realizing the dynamic comprehensive distribution of human and material resources;

In the process of warehouse management, not only the terminal database of RFTD warehouse weighing system needs to be supported, but also the terminal needs to be operated manually, thus realizing the dynamic comprehensive distribution of human and material resources.

(5) Comprehensive inventory function of warehouse RFTD warehouse weighing system;

When the inventory of warehouse RFTD warehouse weighing system is carried out, the passive label on the signboard can be read through the handheld terminal, and the goods can be counted, and the data can be returned to the terminal of RFTD warehouse weighing system for processing and inventory.

(6) random spot check inventory inside the warehouse;

Log in to the terminal of RFTD warehouse weighing system, and then search for a certain kind of goods, get the relevant information of the goods, and transmit the data to the handheld terminal. The staff can find the corresponding cargo space according to the transmitted data, and complete the random inspection and inventory work in the warehouse immediately;

(7) Real-time statistical reports, summarizing all kinds of information.

By reading the warehouse identification card through the handheld terminal, the information can be obtained and transmitted to the terminal of RFTD warehouse weighing system, which can realize the summary of the warehouse RFTD warehouse weighing system and make statistical reports.

C. design idea of C.RFTD warehouse weighing system

When the goods are put into storage, they are classified according to the specifications, and put into the corresponding types of storage places, and a signboard is installed for each storage place, and an electronic label is attached to each signboard, which is called an identification label. And each signboard is numbered, and the id number which can uniquely identify the shelf is stored in the label. The staff can read the id number on the label by holding the terminal, and can call the database of the background RFTD warehouse weighing system to obtain the stored information, including the type, name, model, unit, unit price, production date, shelf life, performance, etc.

When goods need to be moved to the warehouse, log in to the software terminal of RFTD warehousing and weighing system, and the RFTD warehousing and weighing system sends instructions for moving the warehouse to the handheld terminal. The warehouse moving personnel find the designated goods location, take out the specified quantity of goods from the warehouse location, and transport the goods to the destination warehouse location, and send the goods to the warehouse location to modify the contents of the shelf label; Send back the information of warehouse moving operation to the site RFTD warehouse weighing system.

The hand-held terminal in the operator's hand scans the inventory signboard, and sends the scanned data to the terminal computer in real time, and the monitoring personnel make inventory statistics and make statistical reports.

When the warehouse management operation is carried out, the tag number can be read to determine whether the position of the current operation is correct. In addition, as long as the id number of a shelf is entered, the relevant information of the id can be retrieved from the online database, so as to realize the function of material storage and realize online browsing and query.

D. composition of d.RFTD warehouse weighing system

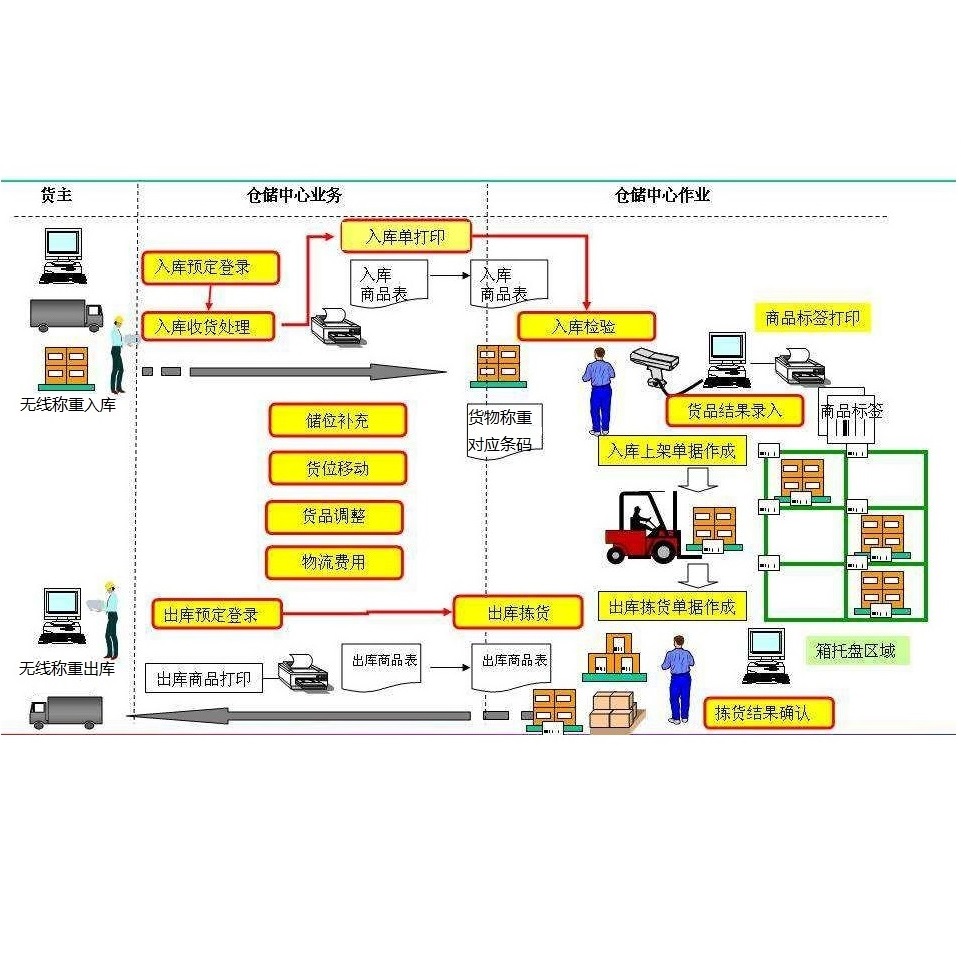

The warehouse management information RFTD warehouse weighing system consists of three parts:

(1) RFTD warehouse weighing system of warehouse management center: responsible for centralized management and maintenance of warehouse management database, formulation of purchase plan and delivery plan, and issuance of instructions; Print and generate various management reports.

(2) The warehouse management site sub-RFTD warehouse weighing system: issuing warehousing labels, real-time inventory management (location management), and issuing warehouse management operation instructions through wireless network.

(3) The warehouse management executive sub-RFTD warehouse weighing system: complete specific operations such as warehousing, warehousing, warehouse moving, and inventory storage, and return to the actual execution.

After adopting RFID technology in warehouse management, it will bring the following benefits to enterprises:

(1) saving the cost of manual data collection;

(2) Automated warehouse management to improve work efficiency;

(3) Reduce management costs and human errors.

(4) more accurate control of stock-in, stock-out and stock-out;

(5) enhancing cooperative partnership;

(6) Respond to customers' demands quickly and expand product sales.