On-line coding and weighing system takes weighing technology as the core, two-dimensional code or RFID as the data carrier, and combines automatic identification and automatic control system to dynamically code and weigh the products in the packaging process, endow each product with a unique "ID card", and at the same time complete the binding of production factor information of products, and realize closed-loop data association at different levels such as single product, box and tray according to the packaging level, providing data for subsequent product weighing, tracking, flow control and interactive marketing.

020-34563445

020-34563445How to realize product association in coding system

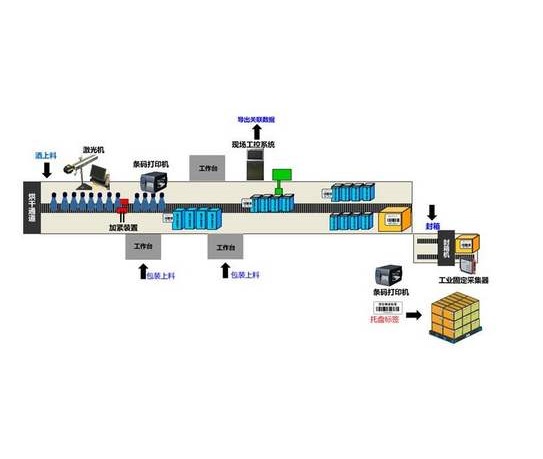

On-line weighing and coding system uses a laser to print a single bottle product on the packaging line of the production line. Under the control of on-site software, after printing a single bottle with a specified number of specifications (for example, 4 bottles per box), the bar code printer automatically prints the box code label and pastes it when packing, forming the relevant data of this box.

In the on-line weighing and coding system, an industrial fixed collector is arranged at the back end of the box sealing machine to scan and collect the sealed bar codes. After scanning the bar codes of the outer box with a specified number of specifications (for example, 75 boxes per tray), the bar code printer automatically prints the tray labels and pastes them at the designated position to form the relevant data of this tray.

Implementation mode of correlation of coding system

1. On-line coding and weighing production line is equipped with on-site industrial control, loaded with industrial control computer, on-site coding related software, PLC controller, board card, etc., which are integrated into one. Coordinate the programmed actions of each part of hardware, and the distribution, correlation and arrangement of field data.

2. On-line coding system: A laser coding machine is installed in the front of the packaging line of the production line, and the single bottle on the assembly line is printed, and the content is anti-channeling code, which is generated by software encryption.

3. On-line coding and Weighing system is equipped with chain clamping device after laser coding is finished, which can clamp the products in each box at a certain distance to ensure the accuracy of data association.

4. On-line coding system is equipped with a bar code printer to print the bar code of each box after the code spraying by the laser machine, which forms an association with a single bottle at this time. Printed labels are placed on every specified quantity of products.

5. The manual packaging of the online coding system will be carried out in groups, and each group will package each box of products. When it is placed in the assembly line again, it should be placed in sequence and keep a certain distance from each box. Products damaged in the packaging process will be replaced or centralized.

6. When the products of the online coding system are packed, the attached bar code label of the outer box is pasted to the designated position, the industrial fixed collector is placed at the back end of the sealing machine, and the bar codes are scanned and collected in turn, and the number of full pallets and the current scanned and collected quantity will be displayed on the customer display screen at the scene.

7. On-line coding system: After scanning the bar codes of the specified number of cartons, the bar code printer automatically prints the label of the tray and pastes it at the designated position to form the related data of this tray. Export the related data of each batch and upload it to the software database.