RFID称重系统实时传输数据到监控计算机,监控计算机也可以随时调用主机数据库中的数据。称重系统对提升货物运输、处理的效率,使得业务管理模式走向条理化、规范化和科学化,从而提高管理水平、降低成本有着巨大的推进作用。作为称重系统的信息(前端)采集工具,远距离RFID技术可以显著提高采集速度,并通过自动识别和防拆卸措施,有效防止人为舞弊给企事业单位带来经济损失。

020-34563445

020-34563445机场的行李系统包括离港子系统和到港子系统。离港子系统包括输送机、行李识别器、自动分拣机、水平分流器、垂直分流器、电控设备及网络链接设备等。行李通过值机柜台办理进入收集输送机,普通输送机的输送,通过RFID系统的跟踪识别,通过水平分流器、垂直分流器的初级分拣将行李运送至指定的自动分拣机进行精确分拣,自动分拣机根据航班划分情况将行李输送至对应航班的离港转盘进行装箱。DCV行李处理系统也叫智能目的地编码小车系统,主要承担高速输送旅客行李的任务,系统分拣存在多条冗余路径,行李分拣可根据最优路径运行,最快仅2min抵达相应分拣目的地,最大限度缩短行李托运交付时间。

行李系统全长32km(皮带系统14km,托盘系统18km),拥有小车约4800辆。该行李系统配备11个值机岛、22条收集输送线、42个离港转盘、21个到达转盘、2个共计可容纳4000件行李的早到系统、2个中转系统、11个三级安检开包间、2套中转再办票系统。系统设计出港行李处理能力为15400件/h,到港行李处理能力为7900件/h,满足旅客吞吐量为4500万年旅客流量。

同时行李系统配备RFID电子标签识别系统,标签上记录有旅客个人信息、出港、到港、航班号等信息。通过RFID读卡器,可高速读取旅客行李信息,解决条码标签被挡住或是行李箱存在多条码等情况,实现高效性跟踪和分拣。早到系统是一套独立分拣系统,采用托盘式存储模式,可容纳量高达4000件。还能按照系统设定精准、高效提取单件或者多件早到行李,提高系统的分拣功能。

新航站楼有两个值机岛均配置全自助行李托运设备,平均分配至国内与国际两边使用。旅客使用国内自助托运设备需要先自行在自助值机设备中值机并打印行李标签,行李绑好标签才能进行自助托运。国际自助则可在一台设备中完成打印行李条码标签,并可在设备引导下绑好行李条码便可完成托运流程。如行李因安全原因需要检查,屏幕会有相应的提示指引旅客到对应的开包间进行检查。

行李处理系统流程

值机柜台设有三段式值机输送机。第一段包括一个磅秤输送带具有承载和称重功能同时也用于贴标签功能,第二段用于柜台式X光安检机的输送控制,第三段负责将等待行李送到收集带。

在值机柜台将使用一次性RFID行李标签。除行李代码以外,在打印时标签中的RFID芯片也会同时被写入除IATA条码以外的用户自定义的额外信息。形状不规则及软包性质的容易在输送皮带面发生滚动、打滑的行李应先被装入行李空筐后再进行输送。

第二段值机输送机即柜台式安检机输送机由行李处理系统负责控制,需实现自锁与互锁功能,即通道上等待判图行李未有结果之前安检机本通道不得进入下一件行李,以及双通道安检机同时只允许一件行李进入。

行李通过安检机后,安检机会对行李内的物品进行检查,检查完成后行李将停留在第三段值机导入线上等待行李安全结果。结果为安全通过的行李将被导入收集输送线,这些行李将受到跟踪,以保证其始终处于安全状态并被装载入DCV托盘并输送到目的地的出发装运转盘。

行李等待安检判读时间有超时限制,默认为2min,超时将状态发送给行李安检系统,行李被送往开包间处理。被安检拒绝的行李也被导入收集输送线中,经由分流器分流至值机岛末端的托运行李开包间进行开包检查。需要进一步检查的行李也被分流至开包间进行处理,行李会被安检人员进一步检查确保安全后方能进入行李系统。经此流程检查合格的行李将被重新扫描标签条码回流至行李处理系统。行李在被导入值机收集皮带之后,至开包间分流点之前,行李处理系统通过PLC追溯式算法对行李进行跟踪。

开包间前的分流点设有行李标签读取设备,读取行李的RFID标签与接收行李安检系统通信服务器发送的判读结果,对比现场安检机的执行信号与上述行李处理系统的PLC跟踪,判断该行李是否应被分流至开包间。安检在开包间分流点处发生跟踪丢失的行李会被送入开包间。开包间入口输送线在显著位置安装拒绝指示灯,区分显示进入开包间的行李状态,包括跟踪丢失,与各种拒绝状态等,指示灯附有相关类型的标识信息说明。行李在被装载进托盘的之前将通过条码/RFID复合型ATR读取标签内的所有信息,并最终与DCV的托盘信息关联捆绑以执行输送和分拣。

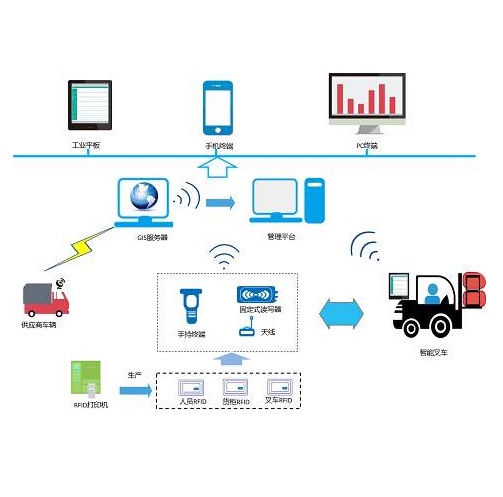

高智能化物流数据系统

智能化数据管理系统对旅客的行李输送、分拣、装箱、装机、卸载等各个环节进行实时跟踪,旅客可以通过APP查询自己行李的位置信息,机场及航空公司则通过大数据的运行系统,可以对每天上万件的行李进行实时核对、监控、跟踪以及查找。国内某些机场在行李条码上绑上芯片,将旅客行李的航班信息、行李信息等植入芯片,当旅客行李进入行李系统时,通过高精端的行李识别装置(RFID)将信息读入行李系统,作为行李在行李系统上跟踪、输送、分拣的依据:通过工作人员的手持终端可以将行李信息读取,作为装箱、装载、卸载以及到港行李信息分配的重要依据,同时行李的数据信息可以实现与旅客共享,旅客通过登录APP方式便可以对自己行李进行全流程的跟踪。

高可靠性的机械设备及备份式的系统

民航机场行李处理系统对行李输送、分拣的及时性、准确性要求较高,所以对行李系统机械设备及装置的要求较高,尤其是机械设备及装置的可靠性。处理系统设计不合理,系统可靠性低,经常性的设备故障导致行李输送、分拣中断或者效率低下,都会带来行李输送延时、航班延误、旅客投诉等严重后果。并且行李处理系统在设计时应考虑机械设备及装置等系统的备份原理,可以通过水平分流器、垂直分流器改变行李流向,通过多台分拣机对行李进行备份式的分拣,多个系统可以单独运行分拣行李,行李高峰时也可以同时协调联动分拣行李,故障时可以相互切换处理行李,从而做到系统备份冗余设计。