The Microwave electronic tag of RFID weighing system is installed near the front of the car frame, and the appropriate installation position is selected according to different structural characteristics of the car frame. At the same time, the frame is made of metal, and metal-resistant electronic tags are needed. In order to ensure that the electronic tag is not damaged during the use, storage and transportation of the frame, the structure of the frame itself is fully utilized to protect the electronic tag.

020-34563445

020-34563445The application technology of truck frame management of Microwave RFID Weighing system makes use of these advantages of RFID weighing system technology to carry out intelligent management. The RFID weighing system reader sends microwave query signals to the electronic tag through the antenna, and the electronic tag is activated by the microwave energy of the reader, and responds after receiving the microwave signals and sends out echo signals with tag data information. The basic feature of radio frequency identification technology is to identify static or moving objects by radio technology, so as to determine the identity of the object to be identified and extract the characteristic information of the object to be identified. At present, it has been widely used in automobile production, transportation control management, industrial automation, warehousing and logistics and many other fields. The truck frame management system of RFID weighing system is a container truck frame management and control system of Sinotrans based on RFID weighing system technology. Based on the successful application experience of RFID weighing system in other fields, combined with the self-demand of container truck frame management of Sinotrans, the automatic identification and tracking monitoring of container truck frame will be realized around the core business requirements based on the principles of automation, advancement, stability and expansibility.

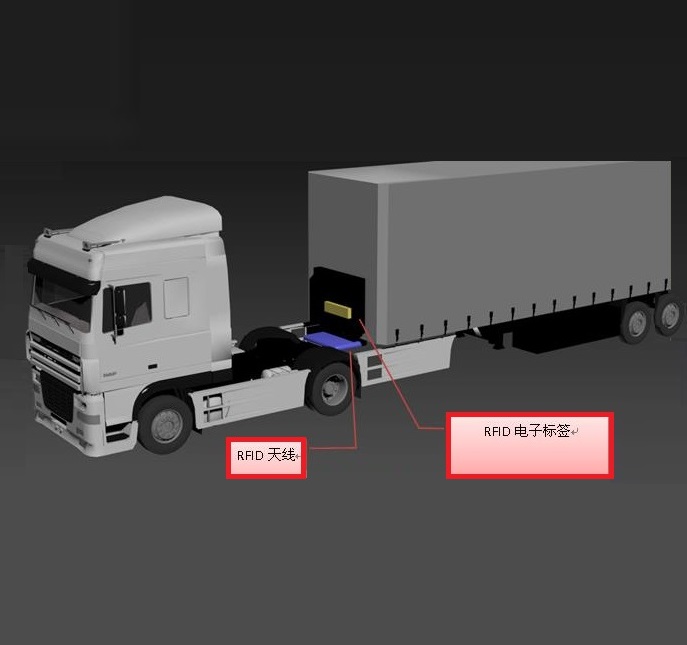

The core of this system is to install RFID weighing system reader and RFID weighing system antenna in the front of the container truck, and install RFID weighing system electronic tag on the frame, so as to monitor and manage the frame through the identification of the electronic tag by the reader. The electronic tag of RFID weighing system is installed near the front of the car frame, and the appropriate installation position is selected according to different structural characteristics of the car frame. At the same time, the frame is made of metal, and metal-resistant electronic tags are needed.

In order to ensure that the electronic tag is not damaged during the use, storage and transportation of the frame, the structure of the frame itself is fully utilized to protect the electronic tag. For the frame without protection position, on the premise of taking into account the reading performance, the metal baffle or buffer rubber is installed to form the protection function for the label. The electronic tag comes with 3M double-sided adhesive tape, and according to the material and environment of the attachment surface, the imported double-sided adhesive tape with high metal adhesion and high temperature resistance is selected, which can be directly attached to the frame, with convenient use and reliable performance. The antenna of RFID weighing system is installed in the front of the car near the frame. Because the size of the RFID weighing system antenna itself is larger than that of the electronic tag, it is difficult to find a suitable position with protective function to install it on the front of the car. In the daily use of the vehicle, it is inevitable that there will be collision events, which will easily damage the equipment installed on the front of the car. In order to avoid this accidental damage as much as possible, this system will adopt an RFID weighing system antenna with a thickened metal alloy on the back of the frame, which greatly improves the tolerance and has strong adaptability to the industrial environment. The reader of UHFRFID weighing system is the core equipment of this system. The application on container trucks should meet the application specifications of vehicle regulations, including dustproof, waterproof and vibration-proof adaptability, and can adapt to the fluctuation of voltage and current. The equipment shell must be durable, corrosion-resistant, and adapt to the requirements of outdoor environments such as high and low temperatures.

The reader of RFID weighing system can be installed in the cab, connected with the antenna of RFID weighing system through radio frequency cable, and the tag information of RFID weighing system can be obtained, so as to supervise the frame. Before the system is used, it is necessary to complete the initialization of electronic tag information, write the unique identification code of the frame into the electronic tag according to the rules or specifications of Sinotrans for frame management, and install the electronic tag on the corresponding frame to complete the establishment of initial data information.

In this weighing control system, the RFID weighing system reader is connected with the vehicle terminal through a serial port, and the data read by the RFID weighing system will be uploaded to the vehicle terminal in real time. After the container vehicle is started, the RFID weighing system reader begins to work; When the car frame with RFID weighing system electronic tag is connected with the front of the car, the electronic tag enters the reader's recognition range, and the reader feeds back the read data to the vehicle-mounted terminal, and the vehicle-mounted terminal sends the data to the background database after processing, thus completing the "boarding task" of the car frame. After the frame completes the "boarding task", the RFID weighing system reader can board the read tag information to the vehicle-mounted terminal at intervals according to the system requirements, and update the working state of the frame in real time. After the frame completes the task, it will be removed, and the RFID weighing system electronic tag on the frame will leave the reading range of the RFID weighing system reader. At this time, the RFID weighing system reader can't detect the existence of the electronic tag, and the vehicle-mounted terminal can't receive the tag information returned by the reader, that is, it is judged that the frame has completed the "getting off" operation. At the end of a complete working cycle of the frame, the system updates and saves the information in real time to achieve the purpose of real-time supervision of the frame. The reader of RFID weighing system should have a wide power adjustment range, so as to ensure that it will not read other frame electronic tags by mistake without affecting the reading performance.