配料秤的由工控机、PLC、工业称重仪表、变频器、振动电机、混料机、传感器、传送带等部分组成。工控机提供人机交互界面,完成控制信息输人、数据管理、进行数据显示、存储、统计和报表等功能,根据操作人员的指令,读取某个编号的配方,然后根据配方中配料的比例及先后顺序,PLC发出开始配料的指令,使得PLC能够起动特定的变频器。

020-34563445

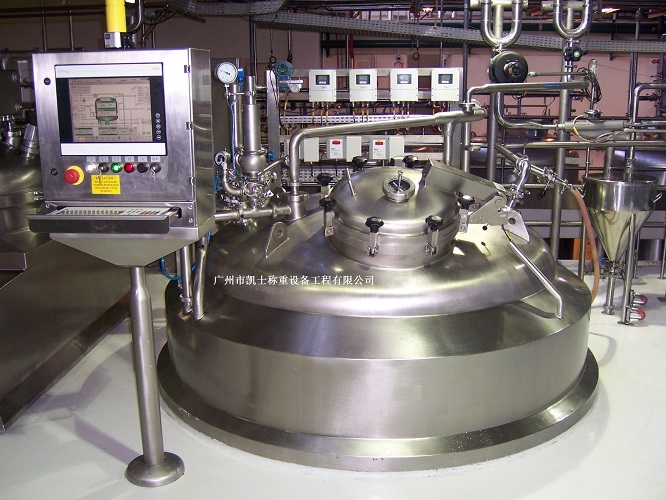

020-34563445配料秤完成主料和各种配料的称重、配比。将配料搅拌混合后,进行分组分类灌装。实现了对配料秤分装的计量,采用DCS集散控制方式,选用西门子S7—300PLC构成数据采集控制系统,模块化设计,经济实用。人机界面监控软件采用国内工控领域头牌组态软件“组态王”,具有开放性好、便于用户维护和二次开发的优点。系统所有过程控制数据及设备运行状态可集中管理、实时记录,随时打印和查阅。配料秤的结构与功能配料秤由计算机、机柜和外围设备(称重反应釜、气动控制阀门、输送泵等)组成。

配料机具有人机交互、通讯、显示及存储、打印等功能,称重模块并具有数据、图形显示,状态监控、数据输入、信息存储等各种有关操作的功能画面。系统可实现实时过程数据监视、模拟显示工艺流程、实时数据记录查阅、系统操作员权限设定、工艺参数设定、设置运行过程事件报警及手动与自动控制切换。监控系统中现场控制仪表实时显示流量、载荷、累计值、温度等。温度指示通过现场温度显示仪表、压力指示通过现场压力显示仪表及电机的电流经现场显示仪表远传至中控室集中显示。变频器调节配备自动切换开关,与主控计算机通讯。

自动称料控制单元主要为一台10寸屏称重配料仪表(相当于10个称重配料仪表),PLC作为辅助控制系统,计算机人机界面显示配比参数(配方)及监控记录实时数据。在自动控制方式下,单击画面中自动配料“启动”按钮,或控制柜“启动”按钮,称重控制仪表就按设定好的配方打开10台秤的称料阀。如果系统检测到某台秤配料阀未关,会发生报警并进入暂停状态。每台秤根据称料快慢设有提前量,当控制仪表检测到秤称料重量达到设定值时,会减去提前量,控制仪表则关闭进料阀。提前量可人为修正或自动修正,使控制仪表控制配料秤每次配料精度达到设定的目标值。

自动配料系统是将已经称好的原料按一定的顺序投放到搅拌配料秤中,称重仪表同时开启搅拌和加热。这一控制过程由温控仪表与PLC共同完成。温控仪表控制温度上限,加热由PLC控制完成。自动配料有固定顺序和可编程序两种控制方式。在固定顺序方式下,各种原料的放料顺序是固定的,不可改变。在可编程序方式下,各种原料的放料顺序可根据配方在人机界面上人为设定。