防爆地磅将称重物体放置在承载秤体上后,就会在承载秤体之上出现一定的重力,由秤体将所受力分布传输给各个称重传感器,在传感器内,将原本的重力信号通过应变片的受力变形后转变成为电子信号,之后再将电子信号传动到接线盒之中进行整理汇合,通过称重仪表采集并处理具体的称重信息,之后就可以将称重值显示出来,另外称重显示器还可以与电脑相互的连接,通过工具软件的整理数据信息,便于用户对数据进行分析、存储等相关的工作。

020-34563445

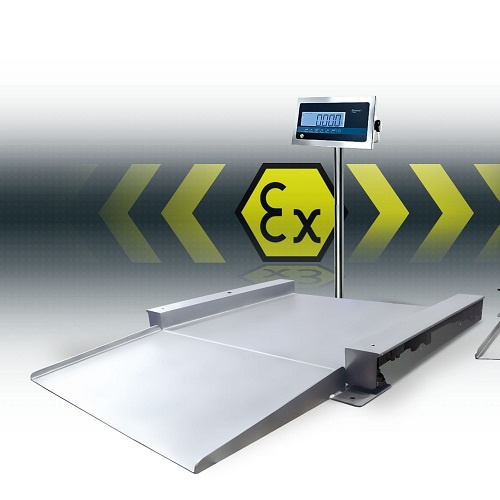

020-34563445防爆地磅在有爆炸性气体或爆炸性粉尘的现场使用,又可按爆炸物质出现的频度、持续时间和危险程度而划分为不同的危险等级区域。采取降压、限流、隔离、密封以及光颖通信等多种技术措施,消灭或阻断衡器电气线路中可能产生的引爆源(电气火花、静电火花、高温……),从而使汽车衡能安全地在相应的危险区域中工作。

防爆地磅将称重物体放置在承载秤体上后,就会在承载秤体之上出现一定的重力,由秤体将所受力分布传输给各个称重传感器,在传感器内,将原本的重力信号通过应变片的受力变形后转变成为电子信号,之后再将电子信号传动到接线盒之中进行整理汇合,通过称重仪表采集并处理具体的称重信息,之后就可以将称重值显示出来,另外称重显示器还可以与电脑相互的连接,通过工具软件的整理数据信息,便于用户对数据进行分析、存储等相关的工作。

技术参数:

台面尺寸:可根据要求定做

精度等级:OLMLⅢ,分度值:≥2000

工作温度(℃):(仪表-10至+40)(秤体-30至+65)

使用电源:AC220V(-15%至+10%),频率:50±1

标准配置:

称台一套(含传感器,连接件,接线盒)。

隔爆称重显示仪表一台。

打印机一台(非防爆区使用)

预埋底板,限位支座,紧固件各一套。

信号电缆一根(50米)。

选择附件计算机及称重软件,大屏幕显示器,稳压电源(非防爆区使用)。