Explosion-proof electronic scales used in production, processing, transportation and storage of various processes, in the petroleum, chemical, coal, national defense and many other industrial sectors, often may leak or overflow a variety of flammable and explosive gases, liquids and a variety of dust and fibers. These substances mixed with air, may become a mixture of explosive hazards, when the concentration of the mixture reaches the explosive concentration range, once the source of ignition that will cause an explosion and fire and other serious accidents. All electrical equipment used in such hazardous environments must be certified by an organization as having explosion-proof performance.

020-34563445

020-34563445Explosion-proof Electronic scales used in the production, processing, transportation and storage of various processes, in the petroleum, chemical, coal and other national defense and many other industrial sectors, often may leak or overflow a variety of flammable and explosive gases, liquids and a variety of dust and fibers. These substances mixed with air, may become a mixture of explosive hazards, when the concentration of the mixture reaches the explosive concentration range, once the source of ignition that will cause an explosion and fire and other serious accidents. Electrical equipment used in this type of hazardous environment must be certified by the agency with explosion-proof performance of electronic scales.

Explosion-proof electronic scales by the Internet information technology will be raw material storage management, production equipment control, production process monitoring, (semi) finished product inventory management, production data traceability system and a series of data combination, and integration and packaging to the Internet. After the feeding equipment puts all kinds of different raw materials into their respective scales, the materials are discharged into the scales according to the given ratio of the formula and weighed, and then sent into the hopper for a certain period of time for mixing and uniformly blending into the finished products. Various fixed formulas are input into the computer beforehand, and the computer controls the discharging, weighing and mixing according to the proportion of formulas, and detects the signals from the weighing module in real time, makes judgment, and sends out commands to each actuator of the dosage, so as to realize the automation of the dosage. The whole production system is equipped with a manual control auxiliary mechanism, which can control the operation according to the automatic or manual working mode.

Weighing range: 300kg x 50g, 500kg x 100g, 1000kg x 200g, 2000kg x 500g, 3000kg x 500g.

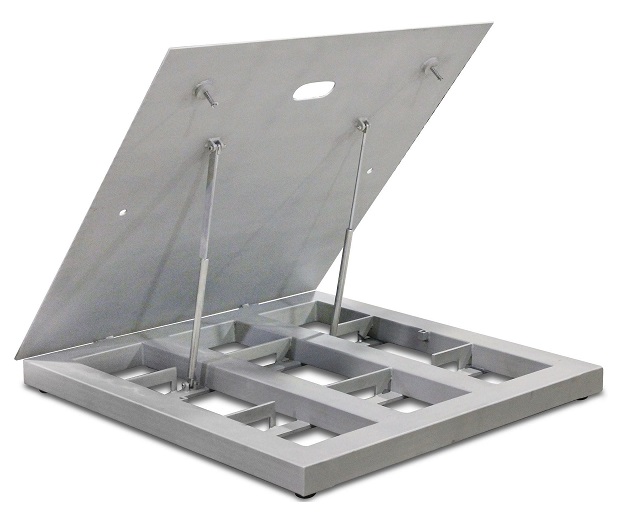

Table size: customized according to requirements, optional stainless steel cover.