PRODUCTS

电子秤通常用于两种以上的原料按比例做批次混合,并以程式控制使批次混合做连续动作,借此达到混合比例得到均匀的效能。采用人机界面输入相应的配比参数,通过称重传感器把每个称重秤的信号传递给称重仪表,再经过称重仪表转换信号和中央控制器连接,中央控制器结合设置的配方根据每台称重的实时数据,控制每种物料的加料时间及加料量。

Product details

020-34563445

020-34563445电子秤通常用于两种以上的原料按比例做批次混合,并以程式控制使批次混合做连续动作,借此达到混合比例得到均匀的效能。采用人机界面输入相应的配比参数,通过称重传感器把每个称重秤的信号传递给称重仪表,再经过称重仪表转换信号和中央控制器连接,中央控制器结合设置的配方根据每台称重的实时数据,控制每种物料的加料时间及加料量。

电子秤主要完成对现场设备相关模拟量和开关量的数据状态采集及输出控制,触摸屏与计量罐PLC配套使用,使得料罐PLC的应用更加灵活。触摸屏可以设置参数、显示数据、以动画等形式描绘生产过程,使得PLC的应用可视化。称重系统釆用RS232接口将触摸屏与PLC通过通信电缆进行连接。远程触摸屏(HMIA)和本地触摸屏(HMIB)通过以太网连接,二者均可显示仪表数据和设备状态,都能对现场设备进行控制。

称重范围:300kg×50g,500kg×100g,1000kg×200g,2000kg×500g,3000kg×500g

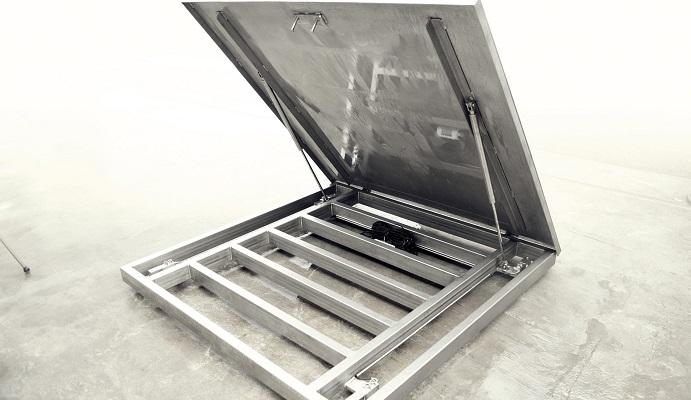

台面尺寸:根据要求定做,选配不锈钢罩盖。