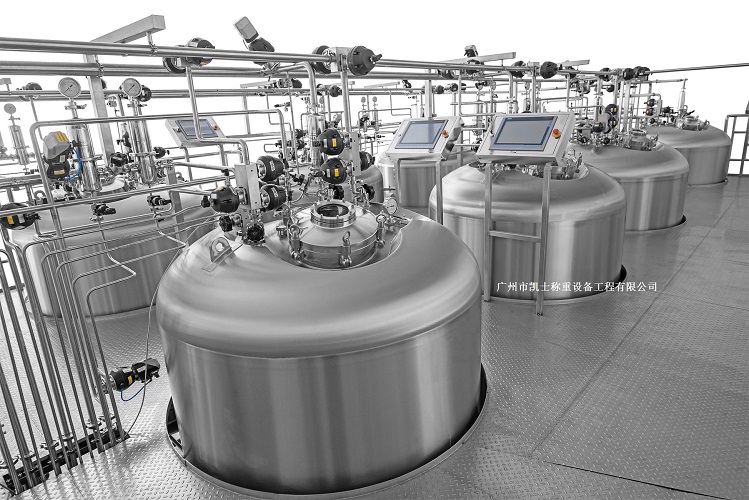

Automatic dosage system is an important part of the reactor mixing production process, through the electronic weighbridge directly collects the weight signal, automatic control of weighing, the operator through the keyboard or mouse in the upper computer human-machine interface (HMI) to enter the dosage information (dosage type, weight, etc.), monitor the whole process of the dosage control, print the dosage of the results and the production of the report, to achieve the integration of measurement, control, and management of the process of the dosage, is a practical and effective way to achieve the dosage process. It is a practical and effective method to realize the integration of measurement, control and management of the feeding process.

020-34563445

020-34563445The dosage machine adopts the regulating valve or changes the pressure of the dosage tank to carry out the dosage, and adjusts the pressure of the dosage tank or the opening of the regulating valve by the PID of the weight value. The standard proportional function and the proportional calculation of the Weighing system are used to ensure the stability of the weighing performance. The given value is multiplied by a multiplier to calculate the target value of the dosage weight, which is given remotely as a control quantity, and the reciprocal is taken to calculate the weight of the discharged material by a multiplier, thus realizing interactive dosage.

It has fully automatic control function and weighing data management function. During the production process it can be according to the process requirements, weighing module according to the predetermined formula, a variety of materials according to a fixed proportion of the weight value of the material will be added to the hopper scales, reaction kettle when the weighing display to the amount of (i.e., to complete the weighing and measurement of each type of material), the reaction tank and then in accordance with the unloading program will be unloaded into the mixer once or step by step many times into the inlet.

Principle of feeding system

1. The weighing material control system collects the weight information on the weighing and measuring tank in real time.

2. The current flow data will be processed in the control system after arithmetic output control signal to the feeding mechanism.

3. At this time, it starts to measure the weight of the material flowing out from the weighing tank, and when the accumulated value is equal to the set weight, the dosing control system will close the valve to stop the dosing process.

Performance characteristics

1. The dosing control system has fully automatic control function and can switch between manual/automatic dosing function.

2. It can be adapted to the harsh working environment.

3. According to the user's demand for formula management, for example, formula input, storage, adjustment, deletion, modification, the software has a confidentiality function, that is, the data in the computer can not be casually copied and downloaded, and so on.

4. During the working process, it can display the batching data in real time, which is convenient to make adjustments in time, manage the weighing data, record the batching data and statistical reports.

5. It can be used for automatic dosage of many kinds of materials according to the requirements of the formula, and it has the function of automatic sealing to the accessing and discharging ports in the process of dosage, and it can realize the function of dust collection in the process of dosage;

6. The dosage has accurate positioning of the dosage truck, and the positioning accuracy is plus or minus 10mm;

7. Provide historical data query system, in the case of authorization can query any time period of the dosage parameters, provide printing function, in the case of authorization can print any time period of the dosage parameters;

8. The man-machine interface is clear and easy to understand, the control system can automatically calculate and show the weight of the materials in the storage bin on the display screen, the running status of the automatic weighing, the instantaneous weight, the cumulative weight and other text or image information, with the simulation function of the interface.