The Premix weighing and feeding system adopts the new WINXP system platform, which is faster and more stable. The real-time dynamic production screen shows the production process, and the operation is intuitive and clear; the powerful report function can record and store a large amount of various types of data and tabulate and print, and it automatically prints the dosage report after the completion of each production, and provides the information of date, time, report number, and the actual consumption of each kind of material; the report extraction adopts the PC manual query method. The report is extracted manually by PC, and the end-of-production report is stored in the computer, which can be read indefinitely to ensure the correctness and completeness of the production report. Simple operation, the system has three production modes: manual, semi-automatic and fully automatic.

020-34563445

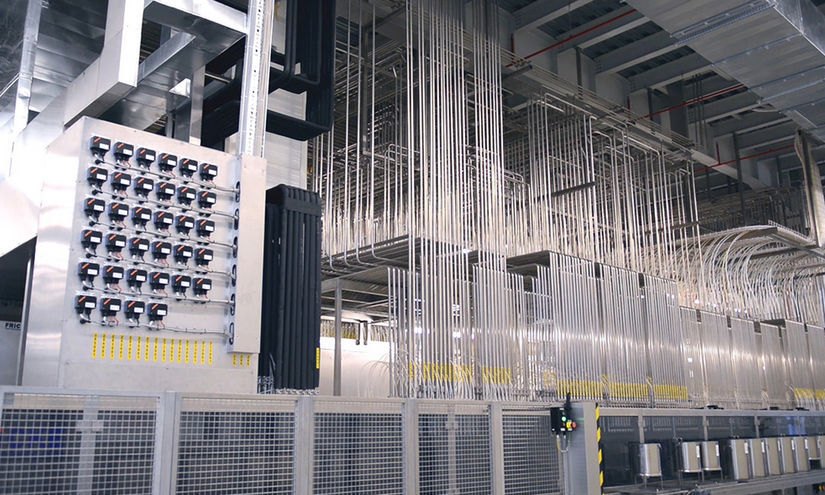

020-34563445Weighing mixer for additives and pre-mixing unit, PLC as the main control of the unit, weighing module to collect the weight of the material in the mixer and should have the position (prompted when the material is lost). Limit switch, when the lifting action reaches the position, it should signal at the proper position. Analog output signal, 4-20mA to 4 valve switches to control the opening, with S type tension to collect the material position and close the valve when the weight reaches the required dosage weight. Has a communication circuit module whose function is to communicate with the console. The communication data is bi-directional and is required to receive information from the console about the specific gravity of the material and the weight distribution of each material mixer.

1) With programmable controller PLC) as the core, small size, high precision, good stability performance.

2) Feeding system can simultaneously control multiple scales, a variety of different materials or control output (depending on the process)

3) Intelligent control of dosage time, no waiting between dosage scales, making the dosage cycle shorter and improving the dosage speed and output.

4) Using the new WINXP system platform, running faster, more stable, real-time dynamic production screen, showing the production process operation intuitive, clear, automatic recovery function.

5) Automatic feeding system powerful report function, can be a large number of records to store all kinds of data and tabulation printing, dosage automatic feeding system automatically in each production after the completion of the printing of dosage reports, and provide the date, time, report number and the actual amount of consumption of each type of material and other information; mixing tank report extraction PC manual query, the end of the production of the report hosted in the computer, can be unlimited read, to ensure the correctness and completeness of the production report. The correctness and completeness of the production report is guaranteed.

6) Simple operation, the system has manual, semi-automatic and fully automatic three production modes.

7) PLC processing data ability, fast and stable sampling rate, the dosage process can fully meet the process requirements dosage.

8) The automatic Batching system process can be set according to the user.

9) two kinds of control programs (touch screen and industrial computer) in the external kind of failure when the other one immediately cut into the operation does not affect the production, automatic Dosage system can eliminate the production failure when the production out of control phenomenon.

10) Real-time graphic display of the production process and text display of the production process, convenient for operators to operate.

11) dosage text file display production reports, formula reports, etc. (there are a number of print content by the user to choose) a powerful alarm prompt function, you can reduce the scrap rate to the extent of the mixing system uniformity, the use of frequency converters to control the speed of discharging the material so that the material in an equal amount of time to put the end of the material to ensure that the dosage of the uniformity of the material.