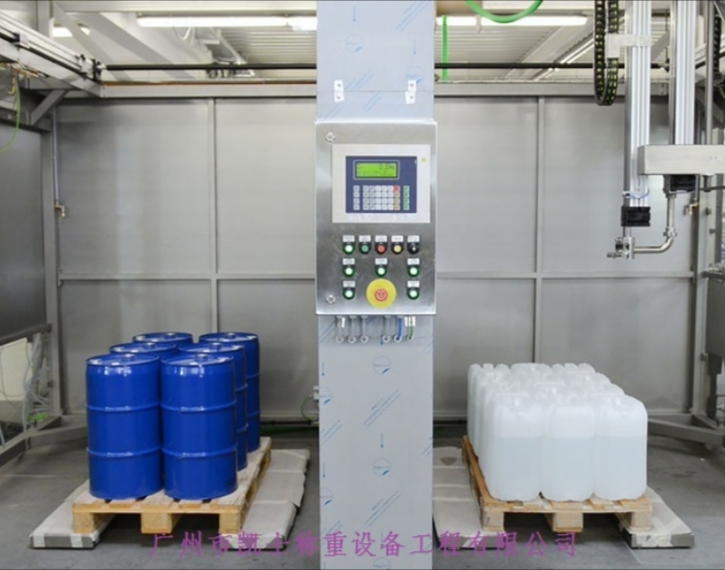

Automatic Liquid filling machine using open bus, field information acquisition, weighing system communication adopted automated filling system, project management, processing, archiving and establishment of documents. With humanized man-machine interface, provide convenience and also have a variety of protection functions, the user can set personalized working parameters according to the actual needs of the user can be set directly into the working state. Simple and convenient operation, no need to wait for restart and other complex operations.

020-34563445

020-34563445The automatic liquid Filling machine is mainly composed of bottle feeding and conveying mechanism, bottle washing machine, filling machinery, capping machine, star wheel conveying mechanism, etc. The process flow is bottle feeding - cleaning - filling - capping - bottle discharging. A mechanical device is used to rotate the container at high speed and then make an emergency stop. Subsequently, a continuous sequence of filling images without any viewing Angle deviation is captured by a mirror in conjunction with a camera. The filling device accelerates the rotation of containers entering the rotating area and stops the acceleration when the containers are about to leave the rotating area, allowing the containers to rotate freely (reducing the bubbles caused by oscillation). When the "container" fully enters the emergency stop area, the light inspection machine will control the mechanical device to make the container stop suddenly. Due to the inertia effect, the liquid inside the bottle will continue to rotate. At this time, the camera starts to capture the continuous sequence of the container through the mirror. The mirror rotates a certain Angle accordingly to ensure that the camera can track and capture the sequence image of the container. The container continues to move forward, and the rearview mirror also keeps rotating accordingly until the container is completely in the emergency stop area. At this point, the rearview mirror immediately returns to the position indicated by the filling machine and starts tracking the next container. At the same time, the continuous sequence image acquisition of the container has also been completed.

The latest product of the automatic filling machine, WinCC-flexible, is a configuration liquid interface for HMI, featuring better openness, scalability and compatibility. It enhances the configuration efficiency of the user interface and brings a new and creative concept of device-level automation. In SIMATIC products, it can be used to configure all Windows CE-based operation panels, ranging from the smallest panels to touch control panels and multi-functional panels. Due to all the above advantages, combined with the control core of the PLC, the configuration of the touch screen is designed based on the CPU313C from the SIMATICS7-300 series. The design for realizing industrial automation. It has some excellent functions, including manual operation, fault alarm, formula management, trend chart (display and analysis), and result printing.

Technical parameters

Weighing range: 10 to 300kg

Filling accuracy: ±0.1 to 0.2%

Filling speed: 3 to 5 barrels per minute (200kg)

Power supply capacity: P≥0.6 mpa, Q≥0.4m ³ /min

Equipment weight: 350kg

External dimensions: 1000ml ×930mmW×1350mmH