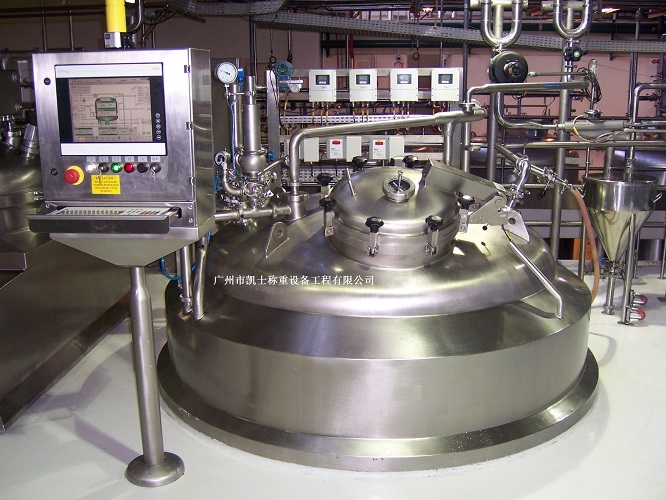

The Traction automatic batching system ensures the real-time communication between the upper PC and PLC, directly collects the weight signal through the electronic weighing, and automatically controls the weighing. The operator input the feeding information (feeding type, weight, etc.) on the HMI of the upper computer through the keyboard or mouse, monitors the whole process of feeding control, and prints the feeding results and production reports. It is a practical and effective method to realize the integration of measurement, control and management in feeding process.

020-34563445

020-34563445The traction automatic Batching system directly enters the corresponding weighing controller through the signal of the weighing module, and the weight signal is transmitted to the programmable controller via the serial port or Modbus protocol of the weighing controller. The programmable controller controls the final control valve of the ingredients in each raw material silo based on the weight of the ingredients to increase the required weight of the raw materials. The S7-200 series adopts 485 bus to achieve communication with configuration. It features functions such as formula setting, ingredient control, ingredient mixing, report printing, and remote alarm, thus realizing remote monitoring.

The overall composition of the batching system is that the host and each slave machine (including virtual hosts) are connected through a serial bus, and the virtual hosts and slave machines are also connected through a serial bus to form a dual-bus structure of master-slave microcomputer batching. The host controls the batching through the serial bus, while the virtual host, after obtaining control of the system, controls the batching through the serial bus. The main unit mainly accomplishes functions such as process flow control, real-time display and alarm of working conditions, data storage, report printing, formula optimization and management consultation.

The batching system can quickly and accurately complete the quasi-dynamic measurement of liquid and powder materials, and can simultaneously conduct real-time quality inspection on multiple liquids and powders. It has functions such as real-time monitoring, data collection, statistics, reporting, and printing of each production link. It can manually or automatically and accurately complete the predetermined feeding, variable frequency stirring, and feeding into finished product tanks, finished product tank barrels, tank trucks, etc. It is widely applicable to the precise measurement and automatic control of feeding, filling and pipeline transportation in industries such as stirring.

Design features of weighing and batching equipment

The continuous dynamic metering method is adopted for the quantitative metering of solid and liquid powder materials, which can control the fast and slow feeding, improving the accuracy and ensuring the production efficiency.

2. It adopts centralized control on the operation console and configuration software development, which can quickly respond to changes in customer demands. The human-machine interface is friendly. Operators can monitor the working status of the production line in the control room, improving efficiency and the speed of handling abnormal situations.

3. The centralized installation of weighing instruments makes communication with monitoring software and PLC more convenient, safe and reliable.

4. The production management software is powerful and can complete various production formula management, process control, abnormal alarm, as well as the collection, storage, report analysis and printing of production data.

5. It is convenient to upgrade and expand. If users need to expand the existing system, they only need to introduce the newly installed sensor leads and valve control lines into the control room and add the corresponding functional modules on the software interface. It is simple and fast.

6. It is equipped with pressure and liquid level detection inside the tank. Liquid level gauges and load cells can be installed in the raw material tank. The centralized control center can monitor the liquid level, pressure, etc. in real time to prevent accidents.