Measurement Explosion-proof filling machine can fully realize the management automation of each phase of business link in oil depot and chemical industry, and carry out automated monitoring for each work link of users, so as to assist the management personnel of users to carry out business processing more efficiently and accurately. Based on the LAN environment, through the unified monitoring interface, it automatically collects the dynamic data of each monitoring environment, and forms various reports (such as oil payment report, unpaid oil report, yearly, monthly, daily report, etc.) and detailed tables based on these monitoring data, which is convenient for business statistics and inquiries.

020-34563445

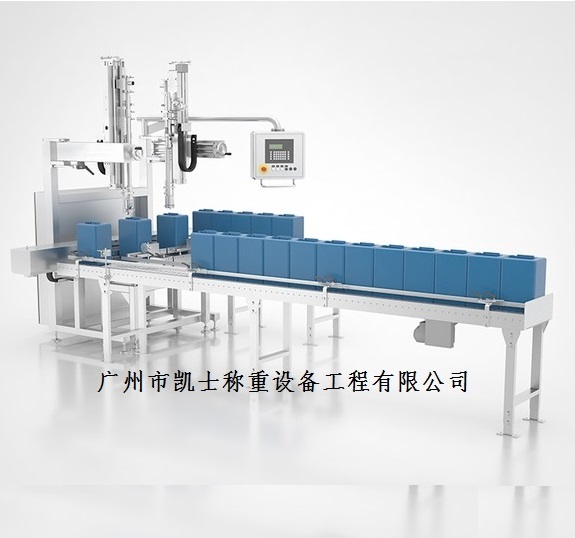

020-34563445The online weighing process of the explosion-proof Filling machine for metering consists of two identical online weighing procedures and an online quality calibration procedure. The two identical online weighing procedures are: one is to pick up and weigh the iron drums on the conveying mechanism before filling and then put them back; the other is to pick up and weigh the iron drums after filling and then put them back. After calculation and analysis by the online Weighing system, the filling error is fed back to the Liquid filling machine for online adjustment of the filling volume.

The online weighing process after filling: When the Electronic scale device at the filling position detects the detection signal of the iron drum being in place after filling, the conveyor belt transmission stops. After the motor of the main shaft lifting mechanism lowers the drum taking rotation main shaft to the position, the drum taking clamp clamps the iron drum after filling and lifts it back into the position, and the conveyor belt transmission starts. The main shaft for taking the bucket rotates to send the filled iron bucket onto the electronic scale. When the main shaft for taking the bucket is lowered into position, the bucket clamping pliers release the filled iron bucket into place. Then, the batching test is carried out and the actual measured mass input signal of the filled iron bucket is output. Then, the bucket clamp clamps the filled iron bucket, the bucket rotating main shaft rises to the position, rotates, and transmits the filled iron bucket to the conveyor belt. When the automatic filling machine's conveyor belt stops, the bucket rotating main shaft lowers to the position, the bucket clamp releases the filled iron bucket, the bucket rotating main shaft rises, and the conveyor belt starts. This completes one post-filling ingredient detection action and repeats this process.

Basic parameters

Maximum weighing capacity: 30kg

Minimum sensitivity: 0.1kg

Filling error: ±0.1-0.2kg

Filling speed: Approximately 1500-1800 barrels per hour for 20L

Control mode: 2-speed control

Filling method: Insertion type, liquid surface

Gun head tubing: Teflon gun head, valve + Teflon hose

Structural material: Main unit SUS304 stainless steel, conveying and palletizing carbon steel anti-corrosion paint.

Scale platform size: 400×800mm(304 stainless steel power raceway)

Empty barrel raceway: 400mm×2500mm(304 stainless steel power raceway), with an additional 1200mm slope unpowered roller

Heavy barrel raceways: 400mm×2500mm(304 stainless steel power raceways,2 sets

Barrel separation device: Suitable for 20L barrels, carbon steel anti-corrosion paint structure, 304 stainless steel raceway.

Palletizing equipment: Translation-type, suitable for pallets of 1200×1200×140mm, including pallet, palletizing and lower pallet conveying.

Pipeline pressure: 0.2-0.6MPa(related to material properties).

Material interface: 4 DN40 flange joints, which can be customized according to the interface standards provided by the user

Air source interface: The user provides a 12mm air pipe connector for quick coupling connection

Power supply: AC220/50Hz(provided by the user to one side of the machine)

Air source used: 0.4-0.8Mpa(provided by the user to the machine side)

Operating temperature: -10℃ to 50℃

Basic conditions: A level and solid concrete floor with a concrete thickness greater than 10cm.

Optional models: Standard type, explosion-proof type filling scale