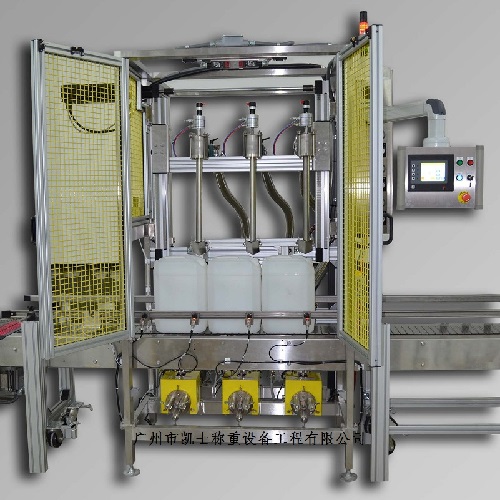

The automatic filling scale adopts the filling method on the liquid surface, which is suitable for filling a variety of non-foaming liquid materials. The uniquely designed filling head device is easy to operate, filling quickly and accurately; and maximize the guarantee of residual liquid dripping when filling is completed. Adopting large turntable bearing and linear rail, it can move around the column left and right, front and back, and the pneumatic operation knob is more convenient for operation, which is easy and quick to operate, with left and right disc brakes and front and rear side brakes, which can prevent the filling gun from touching the mouth of the barrel, and make the filling more convenient.

020-34563445

020-34563445After calibrating the tare weight, the automatic Filling machine outputs a fast-feeding signal to the feeding device, so that the fast-feeding cylinder in the feeding device controls the fast opening of the feeding door, and the material flows into the weighing hopper with a larger flow. Through receiving the signal from the load cell, constantly monitor the weight change of the weighing hopper, when the weight of the material entering the weighing hopper is close to the weight of the fast feeding setting, the system controls the fast feeding cylinder to close quickly, and the fast feeding signal turns into a slow feeding signal, and at this time the material flows into the weighing hopper with a smaller flow rate to ensure that the system controls the flow of the material into the weighing hopper with a higher degree of accuracy.

Liquid filling scale operation includes: calibration of tare weight → fast filling → slow filling → weighing calibration → unloading. The control system calibrates the tare weight, if the tare weight is not zero, the weight compensation gives the filling set weight to ensure that the net weight of the weighed material is not affected by the tare weight of the weighing hopper, and the total is kept at the user's set value.

The control system through the system mathematical modeling, can accurately predict an amount of advance, stop the entire feeding process, so that the final weight of the material in the weighing hopper for the user to set the weight of the system after the end of the feeding into the weighing verification state. The purpose of weighing verification is in the fast and slow feeding are stopped, the system to further confirm that the weight of the material into the weighing hopper in the user's set weight error within the allowable range, if within the error range, the system only unloading operation, otherwise the system alarm, waiting for the operator to deal with, the operator to deal with the completion of the system continues to run.

When the system has finished unloading, the discharge door in the weigh hopper closes immediately, thus completing one cycle of operation. At this time, if the operator set for continuous operation, the system will start the next cycle of operation. The filling bucket which has been filled with material falls on the container, capping, transferring and other processes.

Basic parameters:

Maximum weighing capacity: 30kg

Minimum Sensitivity: 0.01kg

Filling error: ±0.1-0.2kg

Filling speed: 20L about 150-180 barrels/hour

Control mode: 2-speed control

Filling method: insertion type, liquid level up

Gun head line: Teflon gun head, valve + Teflon hose

Structure material: host SUS304 stainless steel, conveying palletizing carbon steel anticorrosion paint.

Weighing platform size: 800 × 800mm (304 stainless steel power raceway)

Empty barrel raceway: 800mm × 2500mm (304 stainless steel power raceway) with another 1200mm slope without power roller

Heavy drum raceway: 800mm×2500mm (304 stainless steel power raceway, 2 sets)

Separate barrel device: for 200L barrels, carbon steel anticorrosive paint structure, 304 stainless steel raceway.

Palletizing equipment: pan-transfer type, suitable for pallets 1200×1200×140mm, including supplying pallets, palletizing, and lower pallet conveying.

Pipe pressure: 0.2-0.6MPa (related to material properties).

Material interface: DN40 flange connector 4, according to the user to provide interface standards

Air Connection: User supplied 12mm air hose connector for quick coupling connection

Power supply: AC220/50Hz (user-supplied to one side of the machine)

Using air source: 0.4-0.8Mpa (provided by the user to the side of the machine)

Use temperature: -10℃-50℃

Base condition: Horizontal solid concrete floor, concrete thickness should be more than 10cm.

Optional models: standard, explosion-proof filling scale