Explosion-proof filling machine can fully realize the management automation of each phase of business link in oil depot and chemical industry, and carry out automated monitoring for each work link of users, so as to assist the management personnel of users to carry out business processing more efficiently and accurately. Based on the LAN environment, through the unified monitoring interface, it automatically collects the dynamic data of each monitoring environment, and forms various reports (such as oil payment report, unpaid oil report, yearly, monthly, daily report, etc.) and detailed tables based on these monitoring data, which is convenient for business statistics and inquiries.

020-34563445

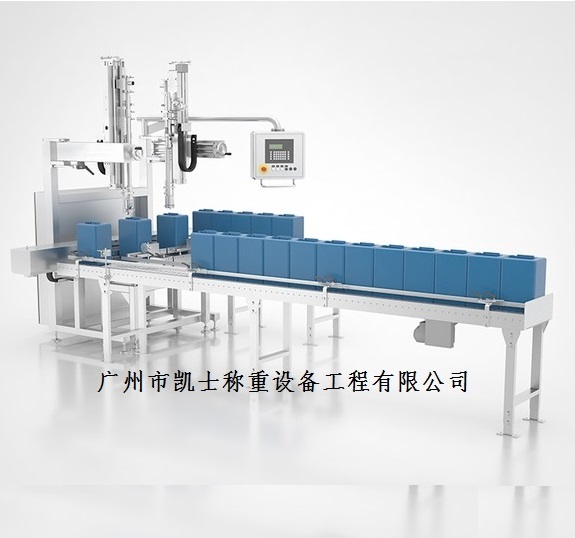

020-34563445The online weighing process of automatic Filling machine has two sets of identical online weighing process and online quality calibration process components. The two sets of identical online weighing process one is to grab and weigh the iron barrels before filling on the conveyor mechanism and then put them back, and the other is to grab and weigh the iron barrels after filling and then put them back. After the online Weighing system calculates and analyzes the filling error and feeds it back to the Liquid filling machine for online adjustment of the filling quantity.

Online weighing process after filling: when the Electronic scale device detects the in-place detection signal of the filled iron drum, the conveyor transmission is suspended, the motor of the spindle lifting mechanism lowers the rotating spindle of the drum to the position, and then the drum clamp clamps the filled iron drum and then lifts it to the position, and the conveyor transmission is started. The barrel rotating spindle transfers the filled barrel to the top of the electronic scale, the barrel rotating spindle is lowered to the position, the barrel clamp loosens the filled barrel and puts it in place, then it carries out the dosage detection and outputs the measured quality input signal of the filled barrel. Then take the barrel clamp clamp after filling iron barrel, take the barrel rotary spindle rise in place, turn, transfer after filling iron barrel to the conveyor belt, automatic filling machine conveyor belt transmission pause, take the barrel rotary spindle down to the position, take the barrel clamp loose after filling iron barrel, take the barrel rotary spindle rise, conveyor belt conveyor start to complete a filling dosage detection action, and so on and so forth.

Basic parameters:

Maximum weighing capacity: 30kg

Minimum Sensitivity: 0.1kg

Filling error: ±0.1-0.2kg

Filling speed: 20L about 1500-1800 barrels/hour

Control mode: 2-speed control

Filling method: Insertion, liquid level up

Gun head line: Teflon gun head, valve + Teflon hose

Structure material: host SUS304 stainless steel, conveying palletizing carbon steel anticorrosion paint.

Weighing platform size: 400 × 800mm (304 stainless steel power raceway)

Empty barrel raceway: 400mm × 2500mm (304 stainless steel power raceway) with another 1200mm slope without power roller

Heavy drum raceway: 400mm×2500mm (304 stainless steel power raceway, 2 sets)

Separate barrel device: for 20L barrels, carbon steel anticorrosive paint structure, 304 stainless steel raceway.

Palletizing equipment: pan-transfer type, suitable for pallets 1200×1200×140mm, including supplying pallets, palletizing, and lower pallet conveying.

Pipe pressure: 0.2-0.6MPa (related to material properties).

Material interface: DN40 flange connector 4, according to the user to provide interface standards

Air Connection: User supplied 12mm air hose connector for quick coupling connection

Power supply: AC220/50Hz (user-supplied to one side of the machine)

Using air source: 0.4-0.8Mpa (provided by the user to the side of the machine)

Use temperature: -10℃-50℃

Base condition: Horizontal solid concrete floor, concrete thickness should be more than 10cm.

Optional models: standard, explosion-proof filling scale