The feeding system adopts Siemens PLC to control the automatic operation of all its interlocking devices (start-stop, interlocking, position switching and other operations), and the upper computer is programmed by Siemens WINCC configuration software. The whole configuration operation screen is embedded into the whole weighing system, and the operation of equipment start-stop operation, operation display, fault inquiry record and maintenance are carried out. The system has the characteristics of friendly interface, concise operation and reliable operation.

020-34563445

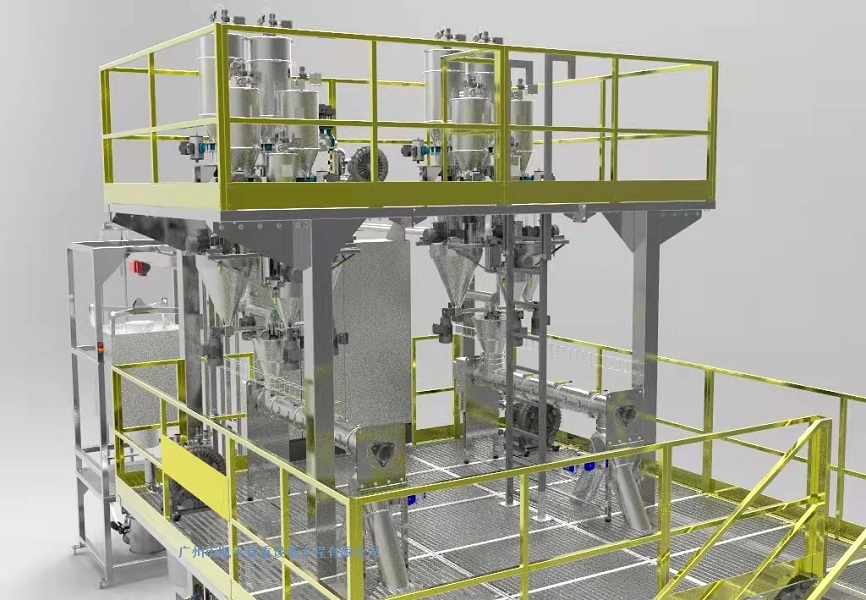

020-34563445Automatic feeding system is a complete set of automatic equipment that realizes dynamic weighing and batching control through electrical control management and visual man-machine software configuration. The electrical control part of the system adopts Siemens PLC, which is programmed and controlled according to production requirements; The software adopts man-machine configuration, and according to the process requirements, the weight and flow of the materials loaded into the weighing hopper are controlled through the monitoring system and PLC program, so as to realize accurate metering and batching. The system has strong stability and high cost performance, and can provide accurate measurement data and control means for production control and management in various industrial fields.

Process description:

This system is an automatic Batching system for high-speed rail brake pads. In the production process, various materials can be automatically batching according to the formula requirements according to the requirements of the technological process and the predetermined formula. After the batching is completed, it will enter the automatic unloading, and after the unloading, it will start to stir, and after the stirring, it will automatically discharge, and so on.

The microcomputer batching control system has the functions of automatic equipment control and weighing data management. In the production process, it can add various materials into the weighing hopper according to the requirements of the technological process and the predetermined formula. When the weight is displayed (that is, the weighing and metering of each material is completed), the materials are discharged into the inlet of the mixer once or step by step according to the discharging procedure.

Scope of application:

1. New production line.

2. Processing and transformation of old production lines.

3. It is suitable for metering and batching powdery materials and liquid materials according to a predetermined ratio (formula).

4. This dosing machine is a non-standard customized batching system according to the actual needs of customers, and it is an automatic batching system suitable for dynamic and static weighing.

Performance characteristics:

1. It has automatic control function of equipment, and can switch between manual/automatic batching function.

2. Can adapt to the harsh working environment.

3. Formulas can be managed according to users' needs, such as formula input, storage, adjustment, deletion and modification. The software has the function of confidentiality, that is, the data in the computer cannot be copied and downloaded at will.

4. During the working process, the batching data can be displayed in real time to facilitate timely adjustment, and the weighing data can be managed and the batching data and statistical reports can be recorded.

5. It can automatically mix a variety of materials according to the formula requirements, and has the function of automatically sealing the inlet and outlet in the batching process, and can realize the dust collection function in the batching process;

6. Provide a historical data query system, which can query the batching parameters in any time period under authorization and provide printing function, and can print the batching parameters in any time period under authorization;

7. The man-machine interface is clear and easy to understand. The weighing control system can automatically calculate and display the weight of materials in the storage bin, the running state, instantaneous weight, accumulated weight and other text or image information of automatic weighing on the display screen, and has the simulation function of the interface.