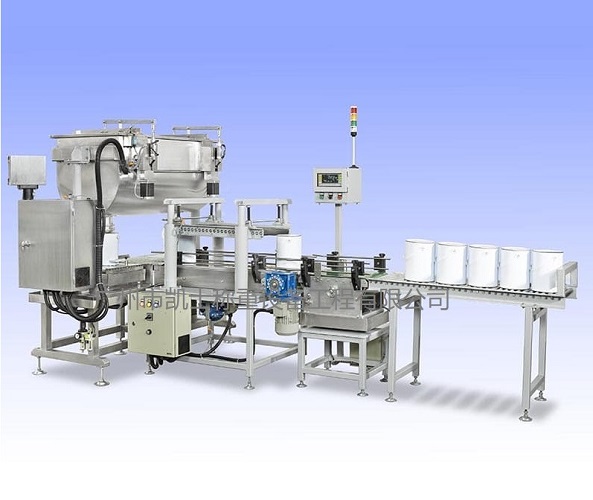

The automatic filling line solves the data communication between the computer and the electronic scale, completes the setting of the raw materials selected in the formula and the standard weight and error weight of the raw materials, as well as stipulates the scale number of the selected raw materials to be weighed. Its main function is to automatically fill liquid materials to a predefined set weight. In the filling process can effectively avoid the material overflow, effectively prevent the material itself on the environment pollution, so as to effectively protect the operator labor. Mainly consists of filling gun device, PLC control system part, electronic scale platform, filling rack platform, conveying equipment and so on. The automatic filling machine solves the data communication between the computer and the electronic scale, completes the setting of the raw materials selected in the recipe and the standard weight and error weight of the raw materials, as well as stipulates the scale number of the selected raw materials to be weighed. Its main function is to automatically fill liquid materials into a predetermined set weight. In the filling process can effectively avoid the material overflow, effectively prevent the material itself on the environment pollution, so as to effectively protect the operator labor. Mainly consists of filling gun device, PLC control system part, electronic weighing platform, filling rack platform, conveying equipment and other components. Liquid filling machine adopts PLC programmable controller, filling head is our proprietary design, sealing system are made of PTFE, the system adopts two-stage size of the material automatic filling method, filling head height can be adjusted by hand, with automatic identification of empty barrel function and empty scale does not fill function, the controller is configured with all the actions of the manual buttons, double-window display of the special filling control instrument, which can display the target amount, The controller is equipped with manual buttons for all actions, double-window display special filling control instrument, which can display the target volume, filling volume, number of barrels, time and date, etc. The controller can store 30 groups of filling value parameters. All-digital tuning, static and dynamic anti-vibration interference software package, controller self-diagnostic function, and interface test function, in case of emergency press the emergency stop button can be lifted this filling. Basic parameters: Maximum weighing capacity: 60kg. minimum sensibility: 10g. Filling range: 10-60kg, filling accuracy: ≤0.1%. Filling speed: 300-500 cans/hour. Container specification: ≤φ300×h350. Material of gun head: SUS304/316; power supply: AC220/50Hz; gas supply: 0.5Mpa.

020-34563445

020-34563445Automatic Filling machine adopts computer automatic control Electronic scale weighing operation, vacuum back pumping system to ensure no dripping, fast and slow double-speed filling to ensure filling accuracy; compact and reasonable structure, stable and reliable work, easy installation and operation. Automatic filling machine has the functions of accurate measurement, fast filling speed, convenient cleaning, anti-dripping, automatic hole pairing and so on. Ensure no dripping fast and slow double-speed filling, ensure filling accuracy automatic socket function, save time arbitrary point stop button, easy to clean the pipeline and deactivation.

Liquid filling scale through the RS485 interface, ModbusRTU protocol communication ARM control system, can realize the automatic switching of self-flow mode and the pump adding liquid mode, the setting of weight parameters, the use of intelligent judgment of the weight, can realize the pump adding liquid operating state, automatically realize the start-stop control of the Filling system, and complete the accurate measurement of the filling volume, display, settlement, printing and other functions, the pressure, The setting of upper and lower limits of parameters such as pressure, weight, temperature, etc. realizes the function of emergency cut-off under the abnormal state of the filling pipeline, which effectively avoids the occurrence of accidents. It can realize the functions of inquiry and automatic totalization of the number of times of liquid refilling, liquid refilling quantity and liquid refilling amount.

Technical parameters:

Filling range: 5-50kg.

Filling speed: 50-120 barrels/hour.

Power supply: AC110/220V.

Power used: 500W.

Air source pressure: 0.3-0.5MPA.

Filling precision: ≤0.3%.

Overall dimensions: 610 x 530 x 1450.

Equipment weight: 70kg.