Medical disinfectant filling machine is connected to the RS232 serial port of the weighing system, after reading the information of weighing data through the serial port, the data exchange and communication between the serial port of the computer and the filling machine will be carried out, according to the need to formulate the barrel ID database and the staff database as well as the weight database, the barrel ID database stores the ID number of the barrel and barrel regulation, etc., and the staff database stores the staff's number and password, etc., and the weight database The weight database stores the vehicle number of the filling station and the weight of each filling.

020-34563445

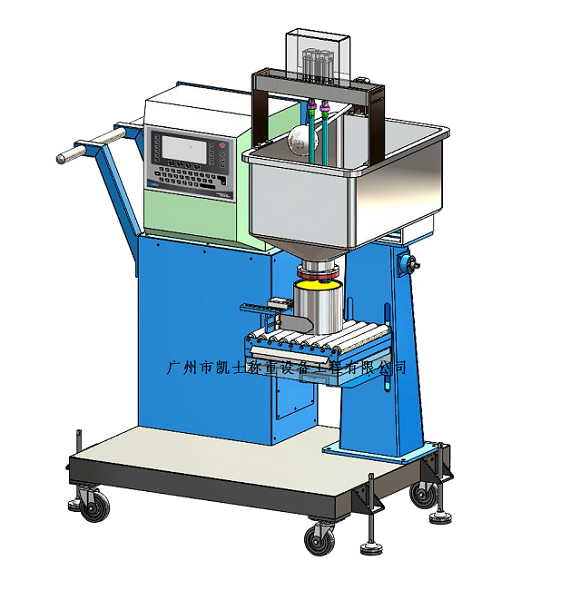

020-34563445The weighing and Filling machine consists of conveyor belt, transmission gear, conveyor belt, conveyor motor and lifting cylinder; the filling device consists of filling gun, filling barrel, synchronization motor, rodless cylinder and roller arm; the suction and sealing cap device consists of cap suction device; and the detecting Electronic scale device consists of photoelectric measuring module, proximity switch and weighing module. Filling process to batch for the production cycle for production, Filling system in strict accordance with the provisions of the work order (recipe) to implement automatic filling machine control program, filling machine to achieve batch production of formula implementation, production flexibility. By means of checking and confirming the instruction information of the feeding process and filling process, electronic signature of important steps, and identification of material and container codes, the correctness of the execution of the automatic filling machine is guaranteed.

Liquid filling machine is accomplished by weighing method, using a platform with a serial port (RS232) preparation, its functions include data acquisition, data processing, generating files, and data printing. In order to adapt to the needs of different specifications of the filling, the system has two working modes, automatic and manual: secondly, the filling parameter setting operation can be carried out manually in the system. Parameter settings include: setting the filling container weight setting (i.e., tare weight), setting the filling weight (i.e., net filling volume).

Generate process production batch reports, material balance and other quality related reports, process data reports, material usage reports, work order reports, etc., through which the analysis of the filling process can be realized. Integration of information technology accessories, such as printers, scanning guns, RFID and other information identification equipment, to give the material into the weighing process of identifiable information.

Basic parameters:

Maximum weighing capacity: 30kg

Minimum Sensitivity: 0.01kg

Filling error: ±0.1-0.2kg

Filling speed: 20L about 150-180 barrels/hour

Control mode: 2-speed control

Filling method: Insertion, liquid level up

Gun head line: Teflon gun head, valve + Teflon hose

Structure material: host SUS304 stainless steel, conveying palletizing carbon steel anticorrosion paint.

Weighing platform size: 400 × 800mm (304 stainless steel power raceway)

Empty barrel raceway: 400mm × 2500mm (304 stainless steel power raceway) with another 1200mm slope without power roller

Heavy drum raceway: 400mm×2500mm (304 stainless steel power raceway, 2 sets)

Separate barrel device: for 20L barrels, carbon steel anticorrosive paint structure, 304 stainless steel raceway.

Palletizing equipment: pan-transfer type, suitable for pallets 1200×1200×140mm, including supplying pallets, palletizing, and lower pallet conveying.

Pipe pressure: 0.2-0.6MPa (related to material properties).

Material interface: DN40 flange connector 4, according to the user to provide interface standards

Air Connection: User supplied 12mm air hose connector for quick coupling connection

Power supply: AC220/50Hz (user-supplied to one side of the machine)

Using air source: 0.4-0.8Mpa (provided by the user to the side of the machine)

Use temperature: -10℃-50℃

Base condition: Horizontal solid concrete floor, concrete thickness should be more than 10cm.

Optional models: standard, explosion-proof filling scale

Optional models: standard, explosion-proof filling scale