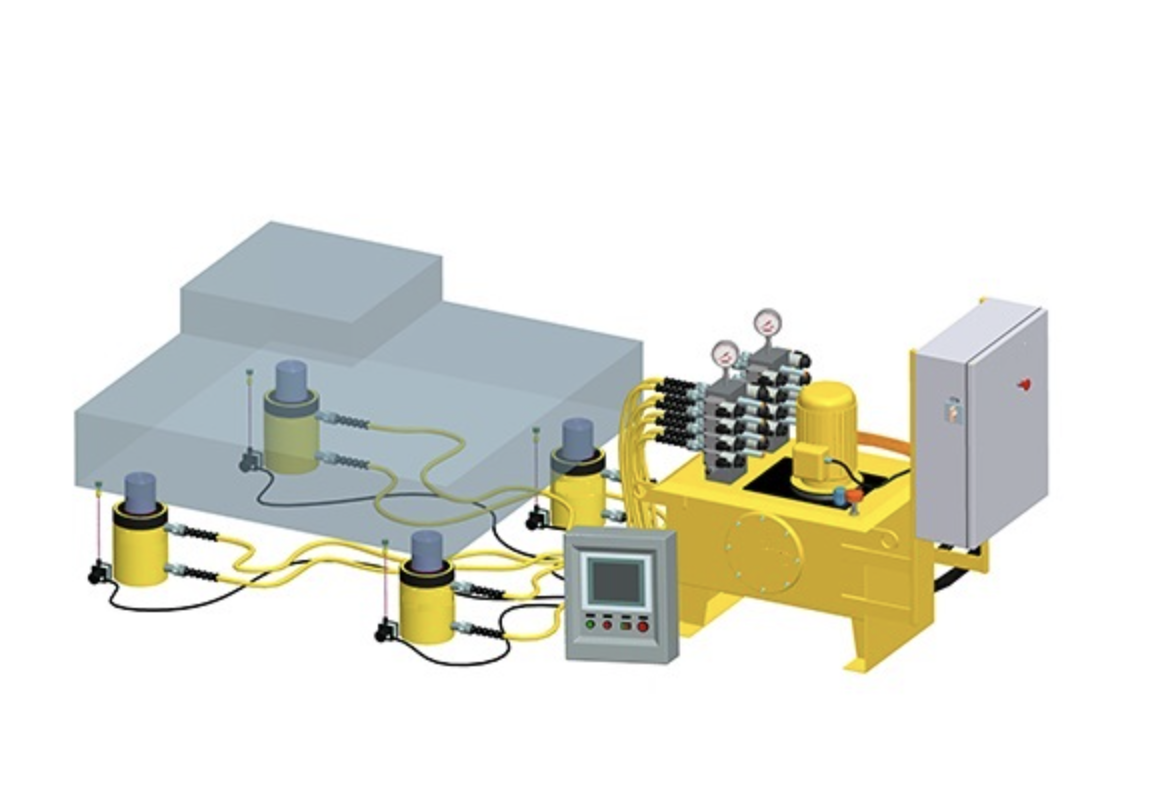

The weighing module uses a certain number of jacks to synchronously lift the structure to be weighed off its support body, transferring the entire weight of the structure to the jacks. The weighing module measures the weight borne by each jack (i.e., the weight of each weighing point), and through calculation, the total weight and the position of the center of gravity of the structure to be weighed are obtained.

020-34563445

020-34563445The weighing module mainly uses hydraulic jacks to synchronously lift the structure to a certain height away from the temporary support. After holding the pressure for a period of time, the oil pressure in the jack pipelines at each pile leg is measured, and then converted into weight values to calculate the overall weight and center of gravity. The combination of synchronous lifting by jacks and measurement by weighing sensors greatly improves the measurement accuracy.

The weighing module uses a hydraulic jack as the actuator. Through the reciprocating motion of the jack, it realizes the lifting, supporting and lowering processes of the large offshore platform. By matching and installing the weighing module with the jack, the weighing sensor measures the weight value on each jack, and the displacement sensor measures the displacement value of each weighing pile leg. The on-off of the oil inlet and outlet circuits of the jack is controlled by solenoid valves, and the lifting and lowering of the jack is controlled by solenoid directional control valves. Through the data acquisition system, the signals from various sensors are accurately fed back to the computer for calculation and analysis. The multi-point synchronization of the lifting and lowering of the large offshore platform is controlled by displacement values and weight values, achieving fully automatic control of the weighing process.