Weighing and sorting scales measure the weight of products during the transfer process, compare the measured weight with a pre-set weight range, and automatically reject products that do not meet the weight standard, or pick products with different weight ranges into a designated weight class area.

Online weighing and inspection machine is a kind of assembly line equipment for automatic weight inspection, which is mainly used for dynamically inspecting whether the weight of the products is up to standard and qualified, so as to judge whether there are missing parts, product attachments or overloaded and overweight in the product package.

Sorting machine workflow: measure the weight of the product during the transmission process, and compare the measured weight with the pre-set weight range, and automatically reject the products whose weight is not up to the standard, or pick the products with different weight ranges into the designated weight class area.

It can quickly carry out weight inspection or weighing of the items on the production line, the inspection standard weight can be set, the real-time display of the inspection weight and quantity, and display the inspection results, automatic counting, automatic rejection of substandard products or alarm in the event of substandard products, can be equipped with a computerized touch-screen, Chinese windows, friendly man-machine interface, easy to operate, classification of daily and monthly reports query printing and other functions.

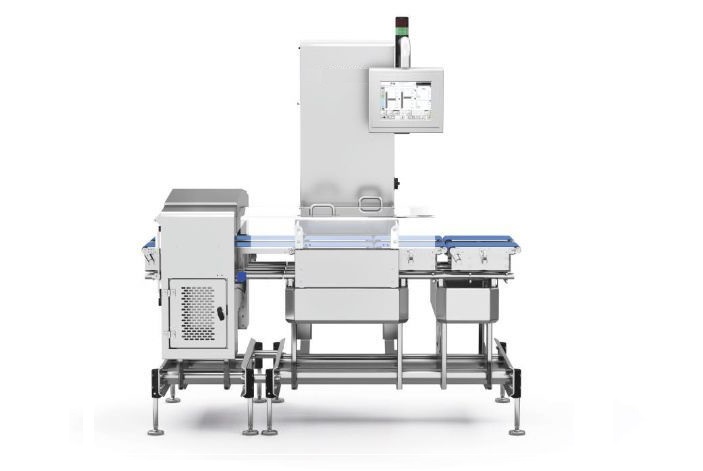

The structure of the sorting machine mainly consists of incoming material speed matching section, weighing section platform, control main chassis and sorting reject section.

The working process of on-line checkweigher

Speed matching section: the weighed product enters the speed matching section first, and its set speed is generally determined according to the spacing of the products and the required checkweighing speed, so as to ensure that only a single product is on the weighing platform.

Weighing section of the platform: the control system recognizes the product to be inspected and enters the weighing section according to external signals, such as photoelectric signals or internal level signals. The load cell transmits the weight signal of the product to the control system.

Sorting and Rejecting Section: When the control system receives the weight signal of the product, the system compares it with the pre-set weight range and rejects or sorts the product.

The main application methods of sorting and rejecting

1) Rejecting non-conforming products directly;

2) Overweight and underweight products are rejected separately or transported to different areas;

3) According to the pre-set different weight ranges, the sorting section can automatically sort the products with different weight specifications into the corresponding weight class area.

The checkweigher provides rich report statistics functions, the number of packages per zone, the total number of each zone, the qualified number, the qualified total number, the average value, the standard deviation and the total number and the total accumulation.

In-line sorting machines are widely used in a variety of industries, such as food and beverage, pharmaceutical and health care products, chemical, hardware, plastic, rubber and other various industries.

Automatic sorting machine is often used in the following occasions:

1, the end of the product weight inspection, in the final part of the product production of the weight of the product to review the weight, the weight of unqualified products removed to ensure that the weight of the products leaving the factory meets the specified requirements. Thus, consumers will not suffer losses due to lack of weight, and the manufacturer's brand reputation will not be damaged because of customer complaints or even complaints.

2, statistical analysis of data feedback, in accordance with the average weight and the nominal weight of the difference between the output feedback signal to the packaging and filling equipment, automatically adjust the average weight to make it consistent with the set weight, thereby reducing production costs. For example, each package of milk powder weight 480 grams, without the use of sorting machines, the average weight of the package is 483 grams to ensure that the weight of the product meets the standard, with the control system feedback, the average weight can reach 480 grams. To produce 10,000 packages per day, the daily savings of 30,000 grams per day, saving 10.8 tons per year, according to the market price of milk powder per package of 15 yuan, the annual savings of 360,000 yuan down.

3, the product leakage check, for large packages containing small packages of products such as beverage boxes, due to equipment error or personnel error factors, will cause the product missing less loaded. The use of sorting machines for large packages for weight checking, can ensure that the large package will not appear in the case of missing products or missing accessories. For example, each case of 24 bottles of beverages, the normal weight of each case is a certain, check the weight of each case can be found in a small number of cases with or without leakage.

4、Automatic sorting and classification, automatic classification of uneven weight products. For example, if the chicken manufacturers want to divide the unevenly sized chicken legs into several weight ranges, they can use the sorting machine to weigh each chicken leg and send the weight signal to the PLC, which drives the corresponding sorting device according to the set range to select the chicken legs into the corresponding sorting area, so as to achieve the purpose of automatic sorting and grading.

5, the above applications are some of the conventional applications of the checkweighing, automatic sorting machine can also be used in the military, the newspaper industry and many other industries, the United States has used sorting machine to check the weight of each bullet, because the weight of the bullet will affect the flight path of the bullet and the lethality. In addition, the automatic sorting machine can also be used in the distribution of newspapers, automatic counting, newspapers in the printing and bundling may not be the number of inaccurate, distributed to the total number of areas may not be accurate, the use of sorting machines for counting quickly and accurately, you can save a lot of manpower.

Advantages of online weighing checkweigher.

1, high-quality weighing and sorting technology: higher sorting accuracy ± 0.05g in China, faster sorting speed of 300 times / min.

2, accurate product sorting function: advanced digital weighing unit and zero point automatic analysis, provide production trend feedback signal, adjust the upstream packaging machine packaging accuracy, reduce costs.

3、Powerful data traceability function: unqualified products query printing, sorting process can generate bar charts, yield charts and other statistical charts, built-in data transmission system for production control.

4、Leading domestic market share: Whether it is industry applications or customer groups, Dongguan Shanan has always maintained the industry leading, with a more comprehensive application experience and technical accumulation.

5、Comprehensive operation of the leading yield: weighing detection sorting action flexibility industry-leading, stable operation, with power failure data storage and fault self-test alarm function.

6, user-friendly design and easy to operate: 10-inch color touch screen operator interface, can be pre-stored 100 varieties, sorting and switching flexibility, to achieve non-stop switching products; modular design, conveyor belt using buckle design, maintenance and cleaning is extremely convenient.

7、Domestic shunt rejection device, to prevent the product in the sorting process to fall down and spill materials, to ensure the integrity of the test object.

8, the depth of development and customization, supporting the ability to integrate: can meet the requirements of different products, different environments to customize all kinds of applicable programs, perfect docking metal detectors, packaging machines and other equipment.