Screw conveyor has a powerful data management function and summary, industrial computer monitoring and PLC detection, calculation and control is the most advanced and most reliable industrial automation control mode. The average continuous trouble-free operation time of Siemens PLC can reach tens of thousands of hours, and is most suitable for strong interference, harsh environment of the industrial site, industrial control computer is also specifically designed for the industrial site, can run continuously, safely and reliably, and industrial computer is one of the best on-site measurement and control of the ideal choice.

020-34563445

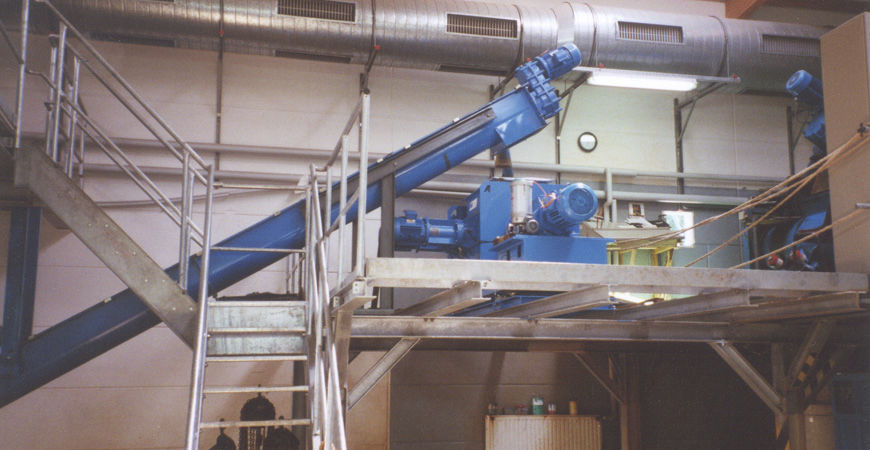

020-34563445Spiral weighing Feeder (spiral scale, reamer scale) is a special batching equipment for continuous weighing, batch feeding and batching of various powdery and bulk materials. The weight signal of the material in the spiral and the speed signal of the spiral running are transmitted to the weighing instrument together, and the instantaneous flow rate of the material and the cumulative output of the material are calculated automatically. By continuously comparing the set flow rate with the actual flow rate of the material being conveyed, the speed of the metering spiral is adjusted constantly, so that the material flow rate can be stabilized on the set flow rate. The weighing conveyor adopts advanced feed-forward regulation system control system, which constantly adjusts the speed of the powder balance locker according to the set feeding volume measurement and achieves very accurate, stable and continuous feeding.

The feeding station utilizes an advanced feed-forward regulation system control system.

The mixer adopts powder balance locker to ensure stable feeding.

Adopting dual control function, simultaneously adjusting . Saving powder balance locker and metering screw, improve the metering precision.

Adopting large inlet, variable diameter, variable distance, and overflow outlet, it ensures that the material sinks evenly, is stable and controlled, and does not collapse the bin, fluff the material, or tamper with the material.

It adopts high-precision digital weighing module and digital transmission technology, which has the features of simple line, no adjustment. Section parts, high resolution, no signal attenuation, strong anti-interference.

The controller adopts touch display technology, Chinese and English graphical display, wizard operation mode, simple operation, no need to remember.

Can be connected to 485 communication, CAN communication, DCS, PLC and other interfaces.

Adopt GPRS wireless digital transmission function, can SMS report, remote diagnosis, calibration scale and other functions.