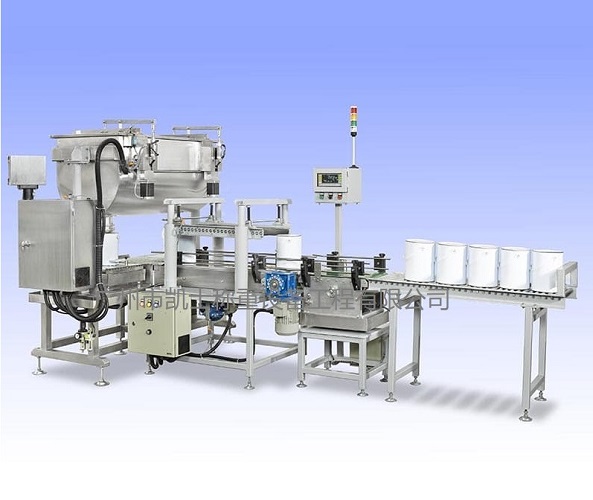

The automatic filling line solves the data communication between the computer and the electronic scale, completes the setting of the raw materials selected in the formula and the standard weight and error weight of the raw materials, as well as stipulates the scale number of the selected raw materials to be weighed. Its main function is to automatically fill liquid materials to a predefined set weight. In the filling process can effectively avoid the material overflow, effectively prevent the material itself on the environment pollution, so as to effectively protect the operator labor. Mainly consists of filling gun device, PLC control system part, electronic scale platform, filling rack platform, conveying equipment and so on. The automatic filling machine solves the data communication between the computer and the electronic scale, completes the setting of the raw materials selected in the recipe and the standard weight and error weight of the raw materials, as well as stipulates the scale number of the selected raw materials to be weighed. Its main function is to automatically fill liquid materials into a predetermined set weight. In the filling process can effectively avoid the material overflow, effectively prevent the material itself on the environment pollution, so as to effectively protect the operator labor. Mainly consists of filling gun device, PLC control system part, electronic weighing platform, filling rack platform, conveying equipment and other components. Liquid filling machine adopts PLC programmable controller, filling head is our proprietary design, sealing system are made of PTFE, the system adopts two-stage size of the material automatic filling method, filling head height can be adjusted by hand, with automatic identification of empty barrel function and empty scale does not fill function, the controller is configured with all the actions of the manual buttons, double-window display of the special filling control instrument, which can display the target amount, The controller is equipped with manual buttons for all actions, double-window display special filling control instrument, which can display the target volume, filling volume, number of barrels, time and date, etc. The controller can store 30 groups of filling value parameters. All-digital tuning, static and dynamic anti-vibration interference software package, controller self-diagnostic function, and interface test function, in case of emergency press the emergency stop button can be lifted this filling. Basic parameters: Maximum weighing capacity: 60kg. minimum sensibility: 10g. Filling range: 10-60kg, filling accuracy: ≤0.1%. Filling speed: 300-500 cans/hour. Container specification: ≤φ300×h350. Material of gun head: SUS304/316; power supply: AC220/50Hz; gas supply: 0.5Mpa.

020-34563445

020-34563445The automatic drum filling line solves the data communication between the computer and the Electronic scale, completes the setting of the selected raw materials in the formula, the standard weight and error weight of the raw materials, and specifies the scale number for weighing the selected raw materials. Its main function is to automatically fill liquid materials to the preset weight. During the filling process, it can effectively prevent material overflow, effectively prevent the material itself from polluting the environment, and thus provide effective labor protection for the operators. It is mainly composed of a gun filling device, a PLC control system section, an electronic scale platform, a filling frame, conveying equipment, etc.

The liquid Filling machine is made with a PLC programmable controller. The filling head is a proprietary design of our company. The sealing system is all made of polytetrafluoroethylene. The system adopts a two-stage automatic filling method for large and small materials. The height of the filling head can be adjusted by hand. It has the function of automatically identifying empty barrels and not filling when the scale is empty. The controller is equipped with manual buttons for all actions. The dual-window display dedicated filling control instrument can show information such as target quantity, filling volume, number of barrels, time and date, etc. The controller can store 30 sets of filling value parameters. Fully digital calibration, dynamic and static anti-vibration interference software package, self-fault diagnosis function of the control device, and interface testing function. In case of emergency, press the emergency stop button to stop this filling.

Basic parameters

Maximum weighing capacity: 60kg

Minimum sensitivity: 10g

Filling range: 10-60kg

Filling accuracy: ≤0.1%

Filling speed: 300-500 cans per hour

Container specification: ≤φ300×h350

Gun tip material: SUS304/316

Power supply: AC220/50Hz

Gas source used: 0.5Mpa