The automatic canning machine outputs a certain number of square wave pulses through PLC programming to control the Angle of the stepper machine and then control the filling feed of the servo mechanism. The circular pulse distributor distributes the control pulses output by the programmable controller to the corresponding winding according to the power-up sequence of the stepper motor. The pulse distribution of the stepper motor controlled by PLC can be realized by software such as filling, capping, sealing, palletizing, weighing equipment and corresponding conveying.

020-34563445

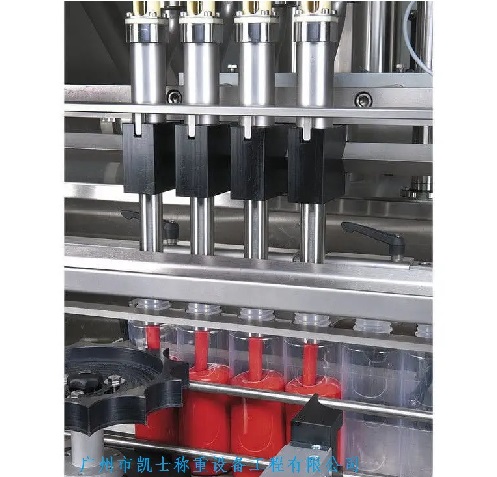

020-34563445Automatic Filling machine adopts frequency control, two speed filling (first fast and then slow), filling head manual screw lifting, to meet the different height of the barrel, weighing table with brake system, to ensure that the barrel does not move during the filling process, touch screen operation, easy to understand, parameter setting. The filling valve is not opened, the pump does not feed, to prevent tube explosion. When the filling nozzle hits the barrel, it is not filled, and the inlet pipe of the filling machine is pumped. The frequency converter controls the flow rate of the pump, which is fast and slow first. The main body is made of stainless steel, which can be filled with most of the high and low viscosity, no particles, non-explosive liquid.

The automatic canning machine outputs a certain number of square wave pulses through PLC programming to control the Angle of the stepper machine and then control the filling feed of the servo mechanism. The circular pulse distributor distributes the control pulses output by the programmable controller to the corresponding winding according to the power-up sequence of the stepper motor. The pulse distribution of the stepper motor controlled by PLC can be realized by software such as filling, capping, sealing, palletizing, weighing equipment and corresponding conveying. In the process of filling and weighing, the PLC receives the signal analysis and processing of the weight in the weighing module, and controls the frequency and stroke of the metering pump to adjust the filling amount. According to the comparison with the standard filling value set by the upper computer, the opening degree required by the filling is calculated by PID algorithm, and the action of the filling valve is controlled, so that the qualified and stable filling weight is obtained to realize the closed-loop control of the filling.