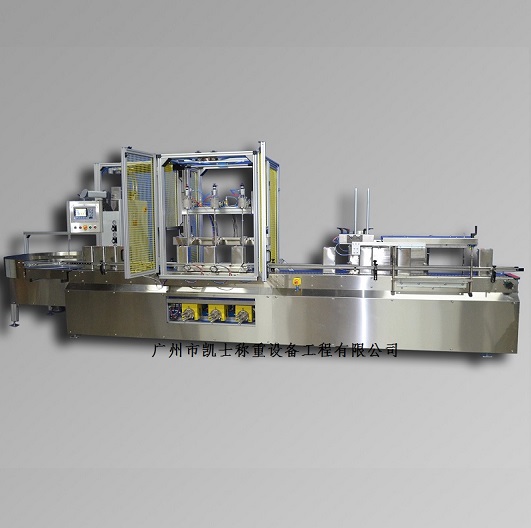

Liquid filling machine Intelligent packaging system designed for liquid drum packaging, diving filling, using high-precision weighing sensor for weighing filling, can automatically set the filling machine, automatic gross weight, net weight filling. Easy to operate.

020-34563445

020-34563445The Liquid filling machine communicates with the central control room through RS485 bus, which can be controlled independently and can be controlled by PLC online. Equipped with monitoring system, with human-computer interaction, communication, display and storage, printing and other functions, and with data, graphic display, status monitoring, data input, information storage and other functions of the operation of the screen. It can realize real-time process data monitoring, simulated display of process flow, real-time data record checking, operator authority setting, process parameter setting, event alarm setting during operation and manual and automatic control switching. The computer downloads the program online through Ethernet PLC and monitors the operation of the equipment. The touch screen communicates with the PLC through the Modbus485 communication protocol, displays the operating status of the device from time to time, and starts and stops the device to set various operating parameters. The actuator is responsible for executing the PLC instructions and executing the corresponding actions in detail.