The automatic filling machine uses a programmable logic controller to comprehensively monitor the running status of related equipment to improve the safe operating coefficient, and to collect and process all kinds of data and exchange data with the server to achieve data sharing.

020-34563445

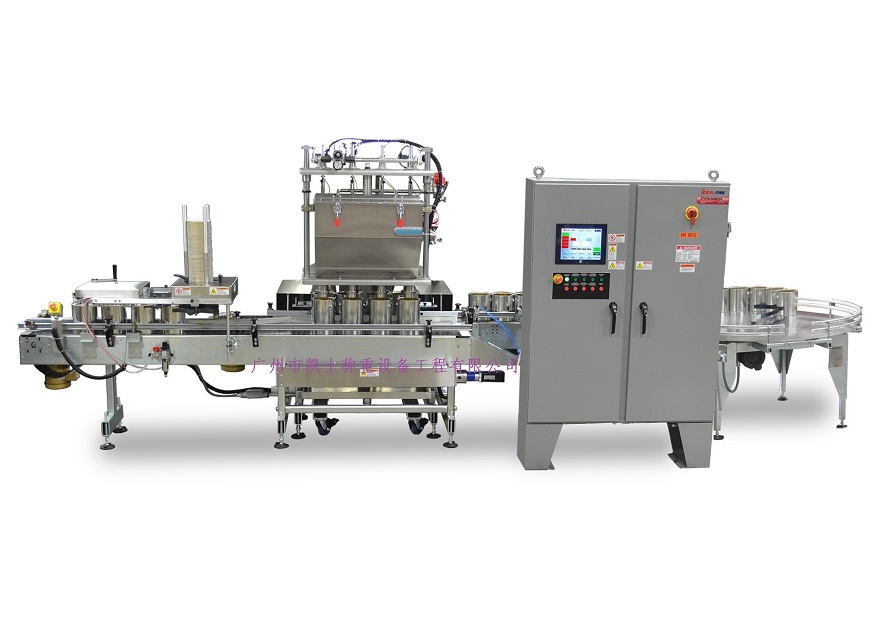

020-34563445Automatic Filling machine is a fully closed integrated paint production hopper equipment, which realizes a series of processes such as automatic bucket management, automatic weighing and filling, automatic capping and automatic stacking. Automatic production is adopted from the access to the paint bucket. Only need to neatly place the paint bucket of the same specification and model in the designated position, and professional manipulator will accurately remove a paint packaging bucket each time. The packaging drum is precisely transported under the cylinder scale of the filling machine by means of a power rail. The filling unit is equipped with an automatic meter that will fill the paint directly into the transmitted packaging drum through the set amount of the filling nozzle according to the preset standard. The whole process is accurate and fast, will not cause waste of materials, and will not cause environmental pollution. The bucket filled with paint will be transferred to the next stage via a power rail.

The bucket filled by the filling machine with the standard amount of paint is accurately sent to the automatic capping machine, and the capping machine uses the manipulator to absorb one bucket cap at a time and accurately place it on the bucket filled with the paint. The automatic sealing machine immediately squeeches the bucket cap accurately with the action to seal the paint filled by the filling machine. At this time, a bucket of paint filling is basically completed. The packing drum filled with paint by the filling machine is sealed and packed and passed to the automatic stacker. The automatic stacker uses a professional manipulator to accurately absorb and place the packaging drum filled with paint into the set tray. When the number of paint drums in the tray reaches the specified number, the robot will automatically transport the tray after placing the paint drums to the specified position.