The weighing bridge of Constant belt scale acts on the weighing sensor through a lever to send the weight of the material detected on the belt to the weighing instrument. At the same time, the speed signal of the belt conveyor by the velocity sensor is also sent to the weighing instrument. The instrument integrates the speed signal and the weighing signal to obtain the instantaneous flow and cumulative amount. The speed sensor is directly connected to the large diameter speed measuring drum and provides a series of pulses, each representing a belt movement unit, and the frequency of the pulse is proportional to the belt speed.

020-34563445

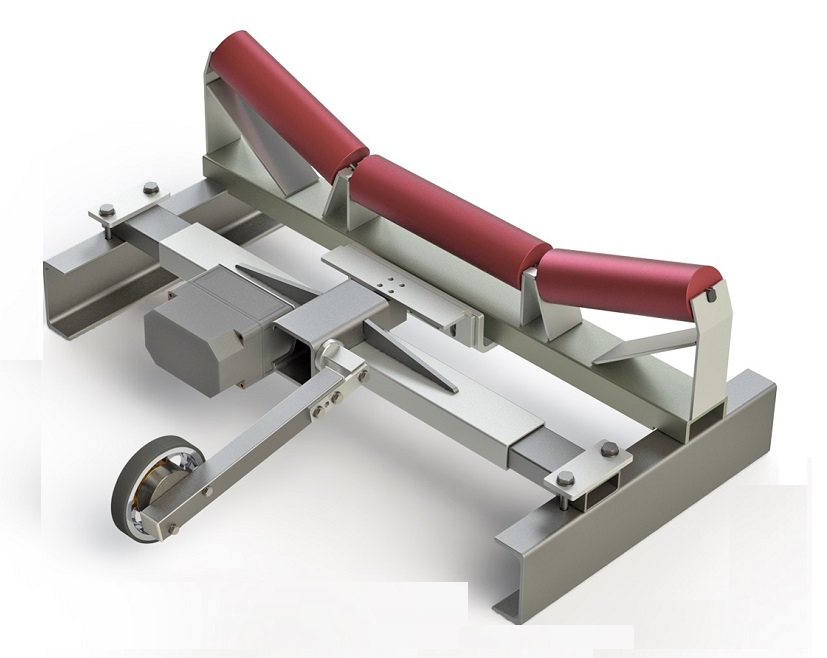

020-34563445The constant belt scale extracts products from the storage hopper through a constant cross-section and adjusts the extraction volume by changing the belt speed according to the set point of the fixed reference flow rate to maintain a constant weighing flow rate. It is mainly composed of four parts: the drive unit, the weighing device, the belt Feeder and the electrical control system. The drive device is composed of a drive motor, a gear reducer, etc. The weighing module device is composed of weighing idlers, Electronic scale brackets, weighing sensors, weighing instruments and belt speed measurement devices, etc. The belt feeder is composed of the drive roller, the driven roller, the bearing idler roller, the receiving hopper, the redirecting roller, the annular belt, the belt tensioning device, the inner and outer cleaning device of the belt, the automatic belt deviation correction device, the guiding baffle and the feeder frame, etc. The electronic control system consists of a control cabinet, control buttons, contactors and emergency stop devices, etc.

The bulk materials in the storage bin flow onto the continuously operating annular belt of the belt scale through the unloading mechanism. The weighing device installed on the feeding scale measures the weight of the conveyed materials and generates a voltage signal proportional to the load of the belt, which is then sent to the weighing instrument. Meanwhile, the weighing instrument receives the speed pulse signal transmitted by the belt speed measurement device installed on the belt scale. After the weight signal and speed signal are integrated and calculated by the weighing instrument, the instantaneous flow value and cumulative volume value of the continuously output material are displayed.

The Weighing system takes the weighing instrument as the core and is used to complete data collection, processing, operation control, display, etc. The object being weighed transmits its gravity to the weighing module in the form of pressure, and the weighing module can convert the gravity acting on it into a linear voltage output. This tiny voltage output is amplified by A low-drift DC amplifier to the voltage amplitude required by the A/D converter. Then, through A/D conversion, the analog voltage is transformed into the corresponding digital quantity, which is processed by the CPU. Finally, the mass of the heavy object is displayed on the LED. Some information can be input through the keyboard to intervene in the operation of the CPU, such as requiring automatic zero adjustment, etc.

The constant belt scale device, due to the fact that the belt conveyor is the best tool for transporting continuous materials, and the belt of the belt conveyor provides a particularly favorable prerequisite for continuous weighing. By measuring the flow rate of bulk materials during the conveying process and integrating the bulk material flow rate, the total weight of the conveyed materials can be calculated. It consists of three parts: the feeder, the belt scale and the control system. Both the feeder and the belt conveyor are driven by variable frequency motors. The belt scale operates based on the lever principle. Under the continuously running belt, a lever device is installed. When the material on the belt passes through the load-bearing surface of the lever device, it will exert a certain pressure on the load-bearing surface. This pressure is transmitted to the weighing module through the lever device, and the control device amplifies and processes the weight and pressure signals sensed by the weighing module and displays them in digital form. At the same time, the displayed digital signals can be externally controlled. The detected bulk material flow signal and the set flow signal are compared within the control system, and the PID is used for regulation. The frequency converter is driven to change the speed of the feeder and the belt conveyor motor. The speed of the belt is automatically adjusted according to the actual required feeding amount, and the given feeding amount is tracked. This forms a control characteristic where the speed slows down when there is a large amount of material on the belt, increases when there is a small amount of material, and even stops when overloaded, thereby achieving a given material flow rate.

The belt scale is an excellent device for continuous measurement of solid bulk materials. It has relatively high precision and is very convenient to apply. Its weakness is that it is open and the dust leakage is relatively serious. The adhesion of dust, the tension of the belt and the flatness of the belt have a relatively significant impact on its measurement accuracy. The maintenance workload is relatively large.

Technical parameters

Single-support accuracy: +/-1%

Multi-support accuracy: +/-0.5%

Suspension accuracy: +/-0.125% to 0.25%

Belt speed: 0 to 6m/s

Remote transmission: 1000m

Conveying inclination Angle: 0 to 30°

Ambient temperature: -20℃ to +50℃

Weighing instrument: 0℃ to 40℃

Power supply voltage: 220V (+10%, -15%), 50Hz±2%

Relative humidity: approximately 150%