Weighing and batching machine puts the weighed raw materials into the reactor in a certain order, and at the same time turns on the stirring and heating, the control process is completed by the weighing instrument and PLC together. The weighing instrument controls the dosing range, and the weight reaches the target value which is automatically completed by the PLC control valve, and there are two control modes of fixed order and programmable program for the dosing. In the fixed order mode, the discharge order of all kinds of raw materials is fixed and cannot be changed. In programmable mode, the feeding order of various raw materials can be set according to the recipe on the human-machine interface.

020-34563445

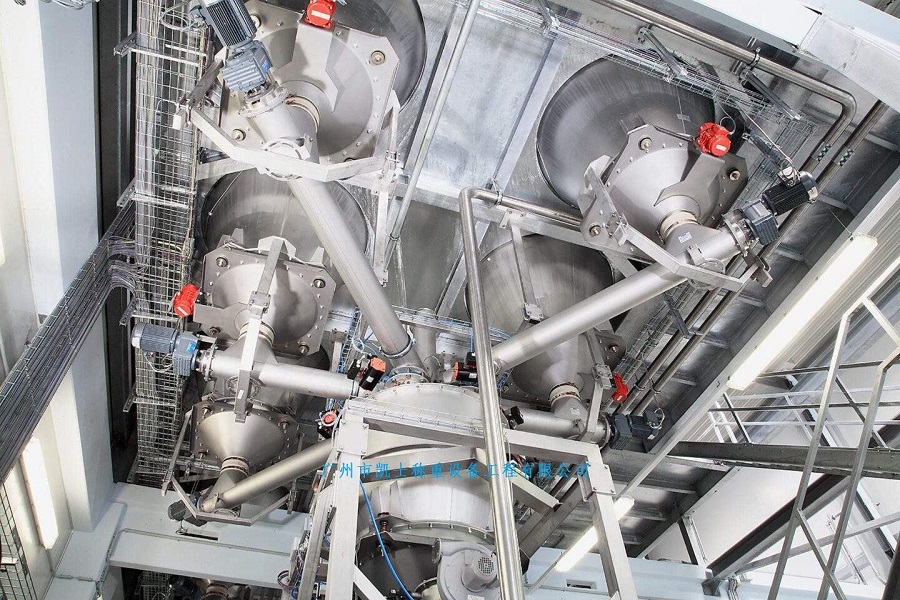

020-34563445Weighing and batching machine is composed of transmission parts, double-layer screw bar agitator and U-shaped barrel. The outer screw strip coiled form with the direction of rotation of the material from the two ends to the middle of the push, and the inner screw strip to the material from the middle to the two ends of the push, the different angle and direction of the screw belt around the law so that the material produces a different flow direction, the material through the continuous convection cycle, shear mixing to achieve rapid mixing. Horizontal mixer cylinder bottom center opening discharge port, the outer spiral belt with the worm gear structure with the direction of rotation of the spindle to drive the inner wall of the cylinder wall materials to the central discharge port, to ensure that the cylinder material out of no dead ends. Typical Case Horizontal Screw Belt Mixer Delivered to the customer is a famous color paste production enterprise in the Netherlands, the photo is the horizontal screw belt mixer tailored for the customer, used for mixing the finished color paste.

Weighing and batching machine with its unique double screw belt design, can make the materials mixed evenly in a shorter time; wide range of application, not only for powder and powder mixing, but also for powder and liquid mixing, but also for mixing pasty, viscous, or specific gravity materials mixing, so that not only for powder and powder mixing, but also for powder and liquid mixing mixing, the discharge valve adopts a curved valve that fits the barrel. The discharge valve adopts the arc valve which fits the barrel, mixing without dead angle, and the design of new valve structure ensures the service life and closing effect of the valve. High loading rate, strong sealing for different material characteristics, the barrel can be designed for 180o-300o, the highest can be loaded with 70% of the material; for ultra-fine powder, the use of air + packing composite sealing structure, to a greater extent, to improve the sealing life and effect, for the liquidity of the slurry, can be configured with mechanical seals, to meet a variety of working conditions of the mixing.

Dosing configuration

1)Storage of liquid: the liquid reactor is made of SUS304 steel plate with actual thickness of 3-5mm.

2)Transportation system: main parts, diaphragm pump unloader, screw holes, positive pressure blower, Roots blower, transportation pipe network, double pass valve, dust system, etc.

3)Mixing system: composed of storage reaction tank, diaphragm pump unloader, spiral, gate, inspection sieve, magnetic separator and so on.

4)High and low air pressure: high air pressure, liquid loading in the middle of the reaction tank at the specified height, high air pressure alarm, supply stop action. Protect the system to prevent clogging. In order to ensure the normal use of metering in the pneumatic, liquid reaction tank, when the metering layer reaches the specified position, a low pneumatic alarm will be issued, the dosage will be immediately supplemented by metering to ensure the continuity of production.

5)Dedusting air: including fan, pulse dust collector, butterfly valve and pipe network.