2020.08.18

2020.08.18Summary:The robot of the explosion-proof filling machine can be used for transportation, loading, unloading, stacking, etc., packaging of clean products that cannot be touched by the human body, such as food, medicine, especially biological products and microbial preparation filling control, and packaging of chemical raw materials harmful to the human body. .

Explosion-proof filling robot can be used for handling, loading and unloading and stacking, etc., the human body can not touch the packaging of clean products, such as food, pharmaceuticals, especially biological products and microbiological preparations filling control: and harmful to the human body of chemical raw materials packaging. With the maturity of robot technology and industrialization, making the application of robot in the field of packaging engineering more and more extensive. There are mainly:

(1) Aggregate packaging cartoning: a number of packaging pieces at a time for a single cartoning.

(2) Bagging of large bags of powder: a one-time loading of powder into a specific soft bag, while completing the stacking of a specific location. For example, cement and chemical products powder bag packing.

(3) High-speed cartoning, folding and sealing multi-station packaging

Some large cartons and trays of multi-station rapid packaging, such as cartons filled with goods after the folding, crimping, sealing and so on.

(4) Heavy lifting and bundling

Heavy products that are difficult to realize by people handling packaging, handling and bundling. Such as metal castings, stacking, bundling, wrapping, especially in the precious non-ferrous metals such as aluminum ingots, copper ingots, zinc ingots. There are also large-scale cold storage of frozen meat and products in the handling and stacking.

(5) the realization of the packaging of brittle items

Packing of bottled products in groups at one time, e.g., bottled beer, bottled soft drinks and other items in filling packages.

(6) Packaging of hazardous liquids Filling of chemicals and pesticides and other liquids that are harmful to the human body.

(7) Identification and detection

For some packaging products and packaging goods in different conditions, different parts of the automatic identification and a variety of information detection, but also has the function of grading and classification.

The above work, relying on manual labor to complete the research and application of robotics.

Types of packaging robots:

(1) bagging robot set the difficulty. Thus promoting

Bagging robot is a fixed rotary seat, the body can be rotated 360 degrees, by the robot to complete the bag delivery, bag opening, measuring, filling, sewing bags and give stacking. This is a kind of packaging robot with high intelligence.

(2) Boxing robot

Similar to the bagging robot, the general metal and glass packaging containers are boxed with rigid box robot to complete. Gripping of the boxed package (items) are mechanical and air suction type two. Can be moved as a whole. Grips or adsorbs the packages, and then feeds them into a box or pallet at a specified position. With the function of directional and positional self-adjustment, it can realize no box (pallet) without unloading and direction adjustment. This type of robot is a more mature robot, widely used. Such as beverages, beer, cosmetics, cigarettes and so on.

(3) Stacking robot

This is a larger power robot.

Requirements for stability and high balance. Its gripping mechanism has a self-locking function in order to ensure that from tens of kilograms to several tons of goods gripped firmly and reliably, it also has a time, position and force parameter control system, through the set control program to achieve.

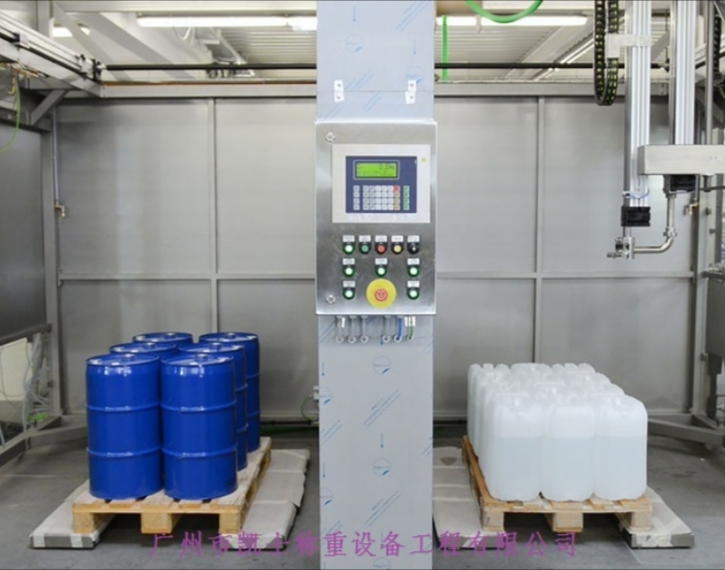

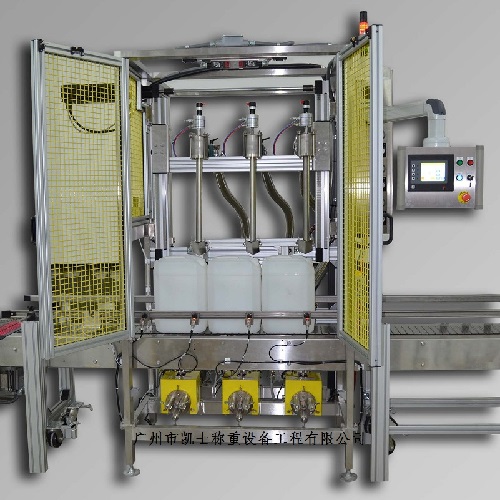

(4) Weighing automatic filling robot

This is a packaging container filled with liquid materials, measurement, infusion cap, cap (cap) and identification of the robot. With no bottle not lose material, no cap not lose bottle, broken bottle alarm and automatic rejection and other functions. In the past a lot of liquid material filling is mainly with the local function of this robot a robot mounted on the production line, and today, it is already this robot directly configured in the material production of the rear of the host, to realize its automatic filling. Filling robots are divided into flexible packaging and rigid packaging. Analyzed here is the hard packaging (bottling) filling robot.

(5) Packaging conveyor robot

This robot in the automatic packaging industry mainly refers to the plastic bottle packaging conveyor robot, is the use of power and special components to achieve the bottle (empty bottle) of the conveyor, the bottle barrel in the packaging bottles in a single rapid output arrangement, and then given a specific (direction, size) of the force. So that the bottle body accurately in the air through the parabolic route to the filling workpiece. This robot changes the traditional bottle conveyor mechanism. It makes the conveying speed faster and reduces the conveying space. Is a new concept of packaging robot. It realizes its conveying operation with the help of aerodynamics and special mechanical components.

(6) Identification and inspection robot

This identification and detection robot is an intelligent sorting system. Separate identification and detection of finished packages and products (such as fruits, etc.) graded identification and detection.

Recognition detection robot with many advanced technologies, mainly recognition and detection technology. Including hyperspectral and multispectral image technology, X-ray flaw detection technology, nuclear magnetic resonance detection technology, infrared detection technology, thermal infrared image detection technology, laser image technology and so on.

Now we focus on analyzing the grading robot in fruit packaging. Non-destructive testing is the key technology to realize the automatic fruit sorting machine. Researchers in the United States have shown that machine vision with ordinary CCD cameras can realize the non-destructive detection of the quality of the external environment of the fruit, with a high accuracy rate. With the help of hyperspectral, near-infrared, mid-infrared and X-ray characteristics, a higher detection accuracy and processing speed can be obtained, which is the hotspot of current research. NIR can also detect the sugar content of fruits, which can be used to evaluate the quality of fruits. In addition, the dielectric properties of fruit, impact detection technology to determine the intrinsic quality of fruit. Fruit in the detection and grading also need to have a specialized grading device, the transmission of information on the results of the test control to achieve the transmission of fruit, orientation and positioning and so on. This is the fruit identification and detection robot technology.