2020.01.28

2020.01.28Summary:The hardware design and software design of the spiral electronic scale with the weighing instrument as the core use the P control algorithm to realize the flow control of the material.Through the reasonable cooperation of software and hardware, the system can realize the function of dynamic weighing, and the measurement error is no more than +2%.

In industrial production, there is a lot of need for accurate measurement and control of the flow of powdered or small granular bulk solids, such as cement plants, ferroalloy plants, aluminum plants, etc. to be accurate measurement of raw material ingredients. Spiral electronic scale is designed for real-time dynamic weighing of industrial raw materials needs, to improve the industrial sector material measurement system has a certain significance.

2 spiral electronic scale hardware design

2.1 The working principle of the spiral electronic scale

Spiral feeding system is designed according to the principle of linear relationship between the Koch force and material mass flow.

Material from the inlet into the cylinder mounted on the screw, the screw speed controlled by the electromagnetic speed motor, the material with the rotation of the screw to move forward, the material in the process of moving forward to be mounted on the screw below the weighing module, measurement module will be part of the mass of the material into a millivolt voltage signal, and through the preamplifier converted to 0 ~ +10V DC voltage signal, and then filtered and the A/D converter After filtering and A/D converter, the digital signal is transmitted to the weighing instrument.

The weighing instrument will process the data in real time to get the weight of the material, on the one hand, the weight of the material will be sent to the digital display tube for display; on the other hand, the weight of the material will be adjusted by PI, and the control quantity will be converted by D/A to output a voltage signal to the frequency inverter, which will control the rotational speed of the electromagnetic speed-regulating motor to adjust the rotational speed of the screw automatically, which will also control the flow of the material automatically, so as to achieve the purpose of controlling the flow of the solid material accurately. The purpose is to control the flow of solid material accurately. In addition, the serial port of the weighing instrument and the PC is converted to level by MAX232, and the data is exchanged through serial communication.

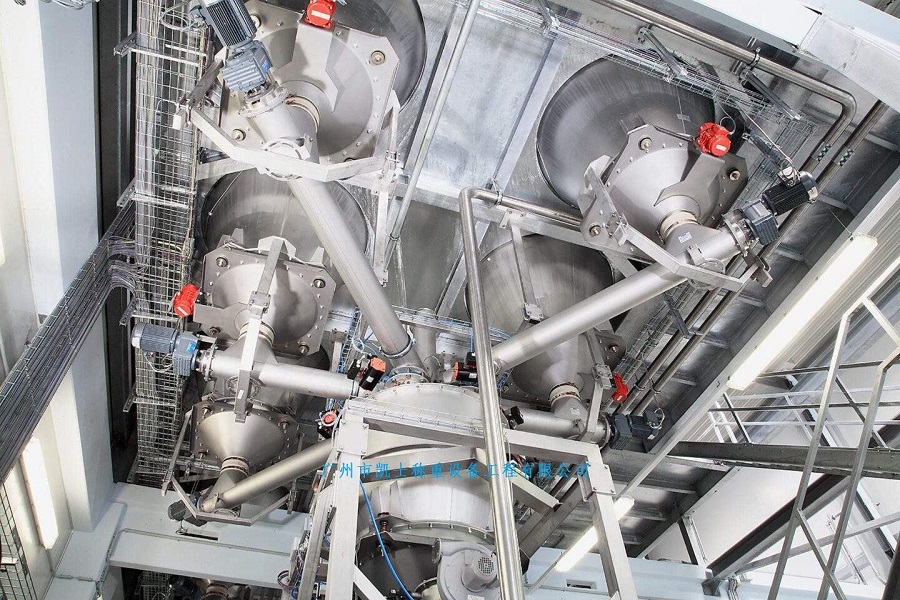

Hardware system of the spiral electronic scale

2.2 Design of Measuring Module of Spiral Electronic Scale

The measurement module of the spiral feeding system mainly includes load cell, signal acquisition weighing instrument circuit and A/D conversion part. a1 plays the role of inverse and full scale adjustment, adjust w to make its output 0~25mV. op-amp a2 is used as inverse zero compensation and filtering, adjust w to make its output 0~10V. in order to prevent the signal of industrial frequency crosstalk interference signal mixing into the weighing instrument and generating the measurement error, the hardware adopts the double T filter with good performance, which is the best choice for the measurement. In order to prevent the industrial frequency crosstalk signal from mixing into the weighing instrument and causing measurement errors, the hardware adopts the double-T filter with good performance. Double T filter parameters should be selected to meet the C = C: = 2C, R = R = 2R, properly adjusted RW, RW, 50Hz industrial frequency interference can be eliminated to get a better filtering effect. A/D converter using the U.S. analog-digital company (Analog) launched the AD574. is a single high-speed 12-bit successive comparative A/D converter, built-in bipolar circuitry constitutes a hybrid integrated conversion chip, with fewer external components, and the ability to convert the signal to a higher frequency. Chip, with fewer external components, low power consumption, high accuracy, and has an automatic zero and automatic polarity conversion function, only a small number of external resistive components can constitute a complete A/D converter.

2.3 Realization of Dynamic Weighing of Spiral Electronic Scale

Spiral every revolution, from the discharge port out of a certain amount of material. To achieve dynamic weighing and to maximize the accuracy of the measurement, it is necessary to minimize the vibration of the feed screw so that the measured value of the weighing module is not the actual value. In order to reduce the vibration of the screw and keep the material inside the screw stable, it is necessary to fix the rotational speed of the screw at a constant value as much as possible, that is to say, to make the rotational speed of the electromagnetic speed-regulating motor constant through the control, so that the output voltage of the weighing module is stabilized at a value, and it results in the weight of the material coming out of the discharge port being equal each time, making △D-0, so that the total weight of the material from the 4→ time period is integrated directly by the cumulative integration method, participating directly in digital form. Methods, directly in the form of numbers to participate in the operation, can change the tonnage of electronic scales, so that the field of physical calibration has become very simple. For this reason, the system uses the rotational speed pulse generated by the screw as an interrupt signal in the hardware, and samples the output signal of the AD574. Weighing instrument data processing of the sampled signal to get the weight of the material, and the weight of the material all the way to the cumulative display, and the other way with the frequency converter given the value of the corresponding weight value for comparison. This produces a deviation signal, which is adjusted by the software PI and added with the automatic preset value to adjust the rotational speed of the spiral, so that the material inside the spiral remains stable, which also stabilizes the voltage on the sensor at a value, thus realizing a more accurate dynamic weighing.

3 Software design of spiral electronic scale

3.1 PI control algorithm

From the spiral feeding system to achieve dynamic weighing process can be seen, the system uses the PI control in the PID control algorithm, through the software to adjust the proportionality coefficient and the integration interval of the sampling time, so that the amount of control given to the frequency converter is a constant value, which also makes the speed of the electromagnetic speed motor is a constant value, so as to stabilize the material in the spiral, so that the output voltage of the weighing module to maintain a constant value, and to achieve dynamic Weighing.

3.2 System Software Design

The software of dosage system adopts modular structure, mainly divided into main program module, initialization module, picking control module and data processing module. The main program control module includes the main monitoring program, keyboard scanning program, display subroutine, etc. The initialization module mainly includes the setting subroutine of analog voltage, calibration coefficients and other parameters as well as the numerical key processing subroutine and prompt display subroutine; the acquisition control module includes the data acquisition interrupt service subroutine and the communication interrupt response subroutine; and the data processing module includes the digital filtering subroutine, the PI adjustment subroutine and the total material integration operation subroutine. The data processing module includes digital filtering subroutine, PI adjustment subroutine, material total integration operation subroutine and so on.

In addition to the hardware filtering means, software filtering is also used to reduce the field interference. The digital filter subroutine is to realize the function of pre-processing the data after A/D conversion, after the A/D conversion is completed, the weighing instrument reads the 12-bit binary data sent by AD574. However, due to the field interference, pulse interference may be generated, so the data must be preprocessed. The median filtering method is used, i.e., every 4 data collected is averaged as the measurement data by removing 1 maximum value and 1 minimum value and averaging the remaining 2 to reduce the spike interference.

4 Conclusion

The spiral electronic scale introduced in this paper takes the weighing instrument as the core and uses PI control algorithm to realize the automation of the working process. Experiments show that the system works stably, the measurement error is not greater than earth 2%, with high reliability, simple operation, and achieve the design purpose.