2020.08.18

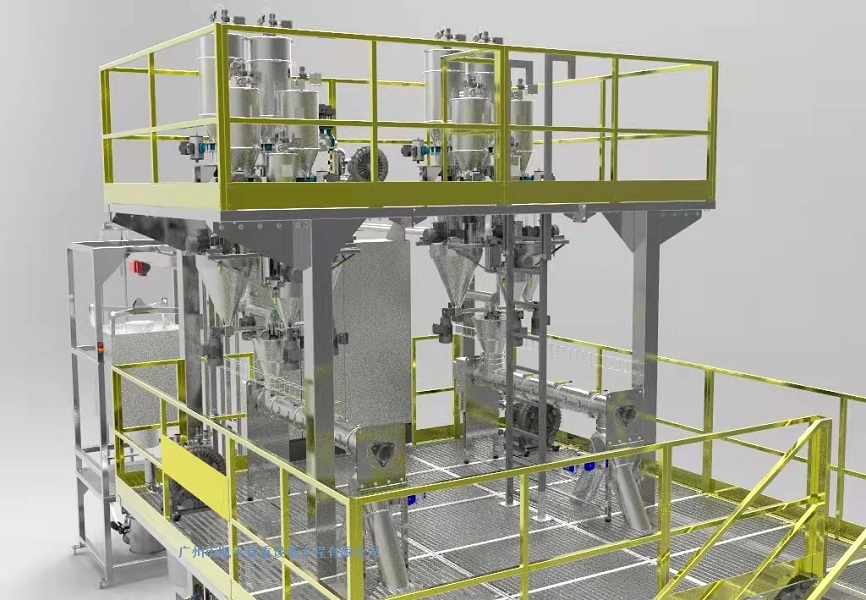

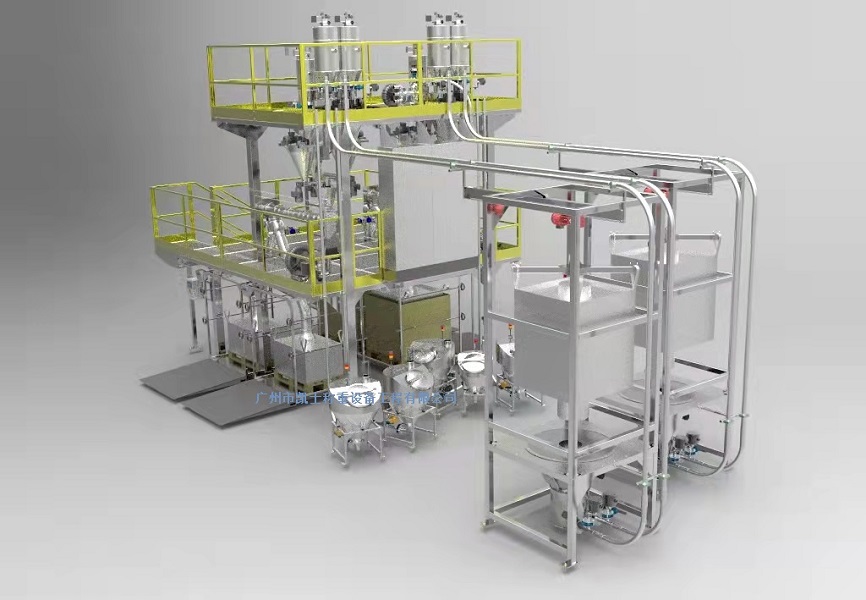

2020.08.18Summary:The batching system manages the entire mixing formula, production data management, equipment operating status management and human-machine dialogue to direct production to meet the mixing requirements of glass production for the mixture.

With the rapid development of modernized society today, the production of industrial modernization has entered the era of innovation in advance. A variety of different specifications of the industrial computer is also widely used in a variety of industrial automation in the production process, it not only meets the users, manufacturers in the operation of the dosage technology and many other aspects of the different requirements, but also in terms of product quality, performance, price and so on many aspects of the majority of users have been favored and unanimously praised. Plastic insulation weighing and dosage system, combined with the successful use of industrial control computer, better for industry, production automation and many other areas of service.

Second, the dosage requirements and application solutions

Germany batching work to reduce costs, the mixing material from gangue to lower-cost slag but due to the new material specific gravity is lighter, resulting in a small platform load, up to the highest belt speed is still not able to meet the needs of the feeding volume. Coupled with the plastic mixing ready to transform the production, its feeding capacity is far from being able to meet the needs of the mixing material for the transformation. Through the transformation of the old equipment transformation technology has a certain understanding of the experience gained, now the transformation process of the problems and solutions to consider the ideas and related technical issues are discussed below: the transformation requirements are as follows: material slag, capacity 1.03t/m3, range: 0 ~ 50t / h, to ensure precision, stable operation, according to the above requirements to develop a program: replacement of the body widening belt to 1.2 meters, replace the corresponding large hopper, replace the reducer, change the DC drive for AC frequency drive, replace the speed measurement and load cell. The original use of silicon controlled dc drive and dc motor, and reducer composed of dc speed dosing, to raise the range must increase the belt speed so the reducer must be changed, the current new production of the feeding system is fully used in ac frequency conversion speed dosing, dc speed has been almost no one uses, the main reason why so mainly because of the low manufacturing cost of frequency conversion speed, easy to maintain, easy to purchase spare parts cheap price. Nine measurement drive part of the maintenance, spare parts procurement has been a problem, by the original size and quality of the DC drive tends to eliminate the impact of factors such as substitution and localization can not be carried out, so it was decided that the transformation of the use of AC speed control. This is for the future of other transformation experience, so as to solve the problem fundamentally. The dismantled equipment can be used as other spare parts to extend the service life of the whole dosage. The original speed measuring device is installed on the special flange between the motor and reducer, so it is necessary to replace the speed measuring device after changing to AC frequency control.

In the work of the plastic insulation weighing feeder, the total work console is required for the whole batching of alarms, interlocks for display and monitoring, while the batching of the whole mixture of formula management, production data management, equipment operation status management and command production of man-machine dialog to meet the production of the mixture of batching requirements. Automatic and manual recipe control of the mixture; automatic control of subsequent equipment startup and shutdown; pre-diagnosis of possible failures; automatic monitoring of the working conditions of the equipment, when the need for technical maintenance, to remind the operator in advance; automatic generation of daily, weekly, monthly and yearly reports, recording the total consumption of raw materials and so on.

For the characteristics of the weighing and feeding system, as the use of computing as the core of the industrial computer, its speed control must be used with high stability, science and technology has made the following configuration program: full use of ACS-2410P industrial computer, the specifications are as follows:

Chassis: ACS-2410P heavy-duty steel box structure, 4U height, 19 "rack standard, can be installed two 5.25" drives and two 3.5 "drives, front / rear panel are provided with keyboard interface, power, fan and overheating faults of the two-color CED alarm instructions

Chassis: ACS-1014P414 slots, 8ISA/4PCI/2PICMG, 4-layer PCB board, anti-interference design, AT/ATX power supply compatible, with PS/2 keyboard interface

Motherboard: ACS-6169VE supports INTELTualatinTMPIII/Celeron processors, 100/133MHz SDRAM up to 512MB, integrated GeForce2MX400 display chip and 32MB of discrete video memory, integrated 1 INTEL82562ET10/100M adaptive Ethernet controller, ISA bus enhanced drive power supply: PS-300W/CPU: PIII1G/memory: SD256M/hard disk: 40GACS-2410P, while the ACS-2410P in its harsh operating environment, are able to work normally, as follows: operating temperature: 0 ~ 60 ℃, relative humidity: 5% ~ 95% @ 25 ℃ (no condensation), the Shock resistance: 10G peak-to-peak acceleration (11ms), vibration resistance: 5-17HZ, 0.1" double peak position

Dosing Principle

Third, the introduction and evaluation of the feeding system

In the plastic insulation weighing and mixing machine, the mixer to the original weighing module combined with the PR1713 weighing instrument composed of electronic weighing as the basis, S7-300PLC as the control core, and equipped with technology industrial control machine, combined with the existing peripheral implementation of the equipment to complete the automatic control of the whole process of dosage from the beginning of the silo outlet to the exit of the mixing machine dosage conveyor mixing.

Combined with the dosage stability of science and technology industrial control machine, not only shorten the development cycle of the project, but also save a lot of manpower; in accordance with conventional practice, if there is no automatic establishment of the technology of the project, the development cycle of this dosage will be greatly lengthened. If the software report using the extended HTML language compilation, not only suitable for storage, printing, but also supports the report of the online publication, in line with the requirements of the network era, for the dosage to retain the future expansion of the interface; TRACEMODE contains more than 150 kinds of process control and data processing algorithms, it is a kind of control function is very powerful software, suitable for solving the application occasions that contain complex control programs. Requirements, at the same time TRACEMODE's human-machine interface development environment provides a wealth of graphic tools, support for AVI video files and the unique amount of appropriate.