2020.02.28

2020.02.28Summary:The batching system sends a discharging prohibition signal to the centrifuge. At the same time, it is in a discharging waiting state and can accept weight instructions for discharging at any time.Start reducing the amount of measurement, and finish discharging the ingredients within 30 minutes at an even speed. After discharging the materials, the batching data and time can be saved.

Due to the different physical characteristics of the split material has a great impact on the split metering, so different ways and means of material metering and control, as well as the hardware configuration of the dosing control system varies greatly. It is difficult to be precise for powder materials with heavy specific gravity or too small specific gravity, high water content, poor fluidity and easy to agglomerate.

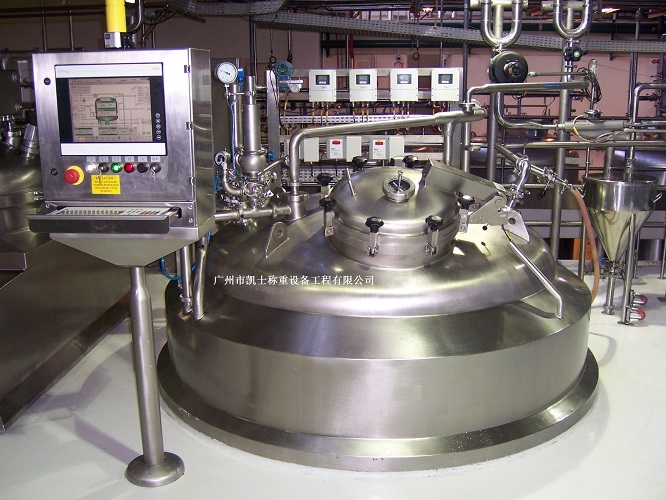

Feeding system for the provision of physical polypropylene clear, analyze the material is easy to wall, easy to bridge, poor fluidity characteristics. For this reason, in the metering tank with a stirring motor, to solve the problem of bridging and hanging wall, with a star-type rotary valve to realize the uniform speed of the material. As there are two motors in the measurement tank, the measurement of the accuracy of the proposed difficulties.

Second, the control system composition

Hardware composition is mainly composed of CPU224XP and metering module, measuring tank 620L has three weighing module support. The weighing module is connected in parallel to the weighing control system through the junction box.

When the calibration of the measuring tank, equipment operation first incremental method for centrifuges from the top of the measuring tank charging for measurement tracking. After the centrifuge has been charged four times or when the material in the reaction tank is greater than 250kg. Measuring and dosing system to the centrifuge to send a signal to prohibit discharging, at the same time in the discharging waiting state at any time to accept the instructions for discharging. Start discharging and using the reduction method of measurement, and to equalize the speed in 30 minutes to finish discharging. After discharging the material can be the dosage system data and time to save.

Third, the control system to complete the function

1、 SIWATOOL MS software calibration weighing

For SIWAREX MS module weighing software SIWATOOL MS is very easy to use, the operation can be independent of SIMATIC S7-200 automated dosage system commissioning. It is connected to the PC Com port via the RS232 interface. In the calibration interface, the weight of the standard weight is entered and sent to the SIWAREX MS module, then when the scale is empty, the "Zero Valid" button is clicked, and the 50KG standard weight is put on the scale, then the "Weight Valid" button is clicked. After putting 50KG standard weight, click "Weight Valid", the calibration work can be completed instantly.

2、Set the low-pass filter frequency

In the online debugging can be based on the vibration of the two motor operation, to adjust the filter frequency, so that it is in the maximum conditions to limit the data of the vibration jump, but does not produce too much lag in the data affecting the accuracy of ultra-differential. Debugging in the dynamic process is very easy to adjust in the monitoring, more intuitive. Figure 4 in the "Limit Frequence" value, set the range from 0.05Hz to 5Hz between the seven optional frequency range. Truly from the point of view of the control application, a flexible solution to the impact of the two motor vibration.

3, PLC programmable function

PLC program can call the ready-made subroutine provided, so as to save a lot of time to write the dosage system program, only need to call the subroutine of a few variables can be, for example: tare, mark zero, display tare weight, etc.. As in Fig. 5 the main program of the SIWAREX MS dosage system, the whole program is visualized for easy operation.

4. Characteristics of the SIWAREX MS module

The SIWAREX MS is a versatile dosage system module for all simple dosage systems and force measurement applications. The compact, modular design is easy to install in SIMATIC S7-200 systems. the SIWAREX MS module accesses the settings and dosage system data directly in the S7-200 CPU and does not require an additional communication interface for data transfer to the PLC.

The SIWAREX MS module also offers the following advantages:

(1) Unified design using the STEP 7-Micro/WIN software package, fully compatible with the S7-200.

(2) Measurement accuracy of 0.05%, with a resolution of 65,000, can be displayed after the decimal point of three or four decimal digits.

(3) Fast start-up and operation of the dosage system functions with the "Quick Start" software package.

4) With rich self-diagnostic function

5) With theoretical calibration function, no need to calibrate the weights.

6) Replacement of the dosage system module without recalibration, all the calibration data of the sensors are stored in the CPU.

7) Easy setup and calibration of the weighing device module through the SIWATOOL MS software, even if you have no PLC related experience, you can easily complete the calibration work.

8) It is certified as Ex-proof area, which is very suitable for chemical applications.

IV. Project operation

The actual dosage equipment debugging situation 250kg of material, the error is between 300g and 500g, the accuracy is about 3 parts per thousand, much higher than the user's expectations of 1%. And two motors running at the same time the value of fluctuations in 200 grams, the entire discharge time control in 25 minutes. This result is very satisfactory to the customer and the way of this dosage system is also very satisfactory. Since the equipment was delivered and used, it has been more than two months, and the operation has been very stable.

V. Application experience

PLC automatic dosage system and its analog module resolution is the value of 4000 and 8000, and the previous solution also need to be equipped with traditional dosage meter, and different brands of products analog data conversion is very easy to cause data distortion. This time, after the introduction of experts, the first choice of dosage solutions, SIWAREX MS module and PLC data in the system directly into process data, with high precision, stable performance and other characteristics, without excessive AD / DA / AD analog-to-digital conversion, will not cause data distortion.