2020.02.11

2020.02.11Summary:The ingredient production control and warehousing management system based on barcode technology realizes comprehensive warehouse management through functional modules such as inbound management, outbound management, and report generation management: barcode technology is used to automatically select the materials with the highest priority.The information storage of feeding operation management is realized, so that the entire process of each material from raw material procurement to use and consumption can be traced.The system not only realizes automatic control of the feeding process, but also can synchronously update the usage of raw materials.

Dosing is an important process in the production process, the accuracy of the dosing will directly affect the final performance of the product. In the production of viscose, different specifications of viscose need different formulas, and in the actual production process, each formula contains several or dozens of raw materials. At present, many enterprises use manual dosing method is not only inefficient, but also prone to error, has not been able to meet the needs of modern industrial production. Dosing control system in the raw material management and storage management is related to each other. In the traditional warehouse management mode, the material in and out of the warehouse is more casual, by manual management of inventory information registration is not only easy to make mistakes, but also affect the speed of goods out of the warehouse, resulting in the loss of inventory items. Once a problem occurs to find the cause and accountability is also more difficult. In the production process, the general requirements of the use of raw materials to follow the "first in, first use" principle. The current manual management can not ensure that workers in the receipt and use of materials in the strict implementation of this principle.

In order to solve the above problems, this paper according to the production management requirements of a viscose manufacturer, the development of automatic dosage system and warehouse management system based on bar code technology. The system realizes the integrated management of warehouse through the functional modules of inbound management, outbound management, report generation management, etc.; through the bar code technology, it can automatically select the most preferred materials to be used, and realizes the automatic control of dosing and the information storage of its operation management. This is to improve the quality and efficiency of enterprise warehouse management, reduce the cost of enterprise inventory, realize the accurate control of dosage and enhance the competitiveness of enterprise market has a certain role.

1 system overall design

Programmable logic controller has the advantages of small size, strong function, simple programming, easy maintenance, high reliability, but the human-machine dialogue is not convenient 3]. The touch screen is a bridge between the operator and the machine and equipment, which receives the commands and setup parameters issued by the operator and monitors the IO status of the PLC and the system operation process in real time. Barcode technology is an emerging technology developed on the basis of computer technology and information technology. Barcode is a kind of special code that represents numbers or letters through the combination of black and white straight lines with different widths, which has the advantages of high accuracy, low cost, simple production, easy to use, etc., and it is a more economical and practical automatic identification technology at present. Configuration King is a kind of open general industrial control software developed earlier in China, which makes full use of the characteristics of Windows graphic functions, good interface consistency, easy to learn and use, and is conducive to secondary development.

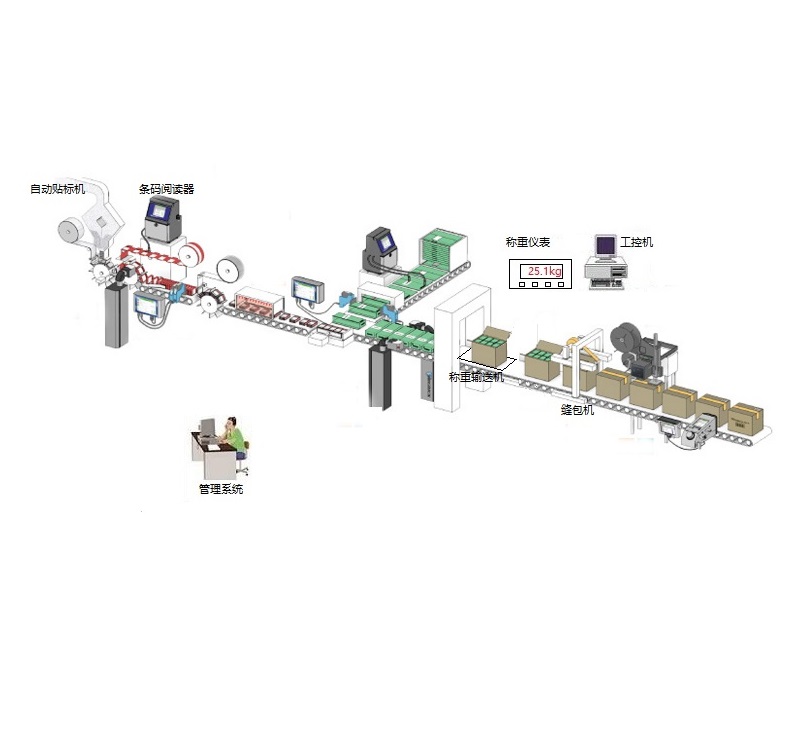

On the basis of synthesizing the characteristics of PLC, touch screen, barcode technology and configuration king, we designed the production control and warehouse management system of ingredients based on barcode technology.

After the raw materials come into the factory, the bar code is firstly prepared according to a certain format and the bar code information is entered into the warehouse management system; then, the bar code label is printed and pasted onto the raw material barrel. When workers receive materials, they must first find the optimal barcode of the type of material in the computer management system, i.e. the earliest barcode of the type of material in the warehouse; and then, through the barcode reader, the adoption information is stored in the corresponding database of the system.

The upper configuration monitoring system mainly accomplishes the following tasks: firstly, it reads and displays the value in the PLC register through RS-485 interface; then, it sends the optimal barcode of each type of material to PLC; finally, it stores the uploaded refilling information of PLC (including refilling time, name of material, barcode, quality of refilling and operator) into the system database for querying.

Communication between the touch screen and PLC at the production site is realized through RS-232 interface, and the touch screen and the barcode reader at the site are connected through USB. When adding material production, select the material name on the touch screen and scan the bar code label of the added material, and compare it with the optimal bar code in the PLC register. If the barcode does not match, the alarm will be prompted and override the start button to prohibit refilling production, thus ensuring that the raw materials are reasonably used in accordance with the principle of "first-in-first-out". When the barcode is the same, it can enter the dosing operation, select the solenoid valve and set the dosing amount, PLC receives the command signal from the touch screen and performs the control task, PLC receives the signal from the load cell and controls the solenoid valve on site to realize the accurate dosing. Each time the dosing information will be real-time stored in the computer and touch screen, and can be saved in the form of Excel to the external hard disk of the touch screen, so that the data processing is more convenient.

Due to the long distance between the site and the upper computer management system, the communication adopts RS-485. Since the computer interface is RS-232 and the PLC communication interface is RS-485, it is necessary to install RS-485/RS-232 converter at the serial port of the computer to solve the problem of matching the communication interface. Taking into account the viscose production site explosion-proof requirements, in the system design, in addition to control cabinets, weighing transmitters, solenoid valves with explosion-proof type, the connection of the signal line should also use explosion-proof junction box and explosion-proof hose.

2 warehouse management system design

2.1 Barcode technology

Bar code is divided into one-dimensional bar code and two-dimensional bar code. One-dimensional bar code is only in one direction (generally horizontal direction) to express information, and in the other direction (generally vertical direction) does not express any information. One-dimensional bar code can improve the speed of information entry and reduce the error rate. However, there are some shortcomings of 1D barcode: the data capacity is small, it can only contain letters and numbers, and the barcode can not be read when it is damaged. Two-dimensional barcodes are barcodes that store information in a two-dimensional space in the horizontal and vertical directions. This type of barcode can be used to represent data files (including Chinese character files, images, etc.). Its cost is high although confidentiality is good. From the actual requirements of enterprise production and cost reduction considerations, this system selects one-dimensional barcode.

A complete one-dimensional bar code consists of two blank areas, start characters, data characters, check characters (optional), termination characters and characters for human readability. Different types of barcodes, there are different code systems and coding methods barcode coding methods have 2 kinds: D width adjustment method, such as 39 code, Kudumba barcode and cross 25 code; 2 module grouping method, such as the general merchandise barcode (EAU code and UPC code) 93 code EAN128 code]. This system uses EAN128 code.

2.2 Storage management

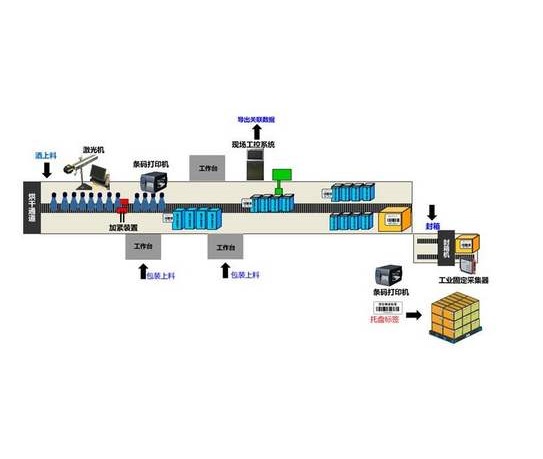

After the production of raw materials into the factory, the raw materials must be warehoused operation. According to the time, type and batch of the raw materials into the warehouse, the raw materials are coded and set and labeled; at the same time, the bar code information is uploaded to the computer management system for warehousing and updating the inventory.

In order to carry out quality tracking, it is necessary to be able to trace the specific raw materials according to the barcode. Therefore, the barcode of each raw material must be unique. The barcode has a total of 12 digits. The information displayed on the barcode label includes: production date, material name, and batch.

Bits 1 to 6 for the production date, for example, September 5, 2016 code for 160905; bits 7 to 10 for the material name, for confidentiality considerations, the factory will be dozens of production raw material names expressed in characters, the material name is less than 4 characters, then the 10th bit with a space instead of; for example, E888, A09, H15, etc.; bits 11 to 12 for the raw material batch, starting from 01, used to Distinguish between the same kind of raw materials purchased within 1 day. The code not only ensures the uniqueness of the barcode, but also has a certain degree of flexibility.

2.3 Outbound management

When receiving materials, first check the balance, barcode and recent use time of all inventory materials in the host computer. Then, find the optimal barcode of each material, and send the queried optimal barcode information to the production site, so as to discriminate when adding materials to the production. Finally, workers go to the warehouse to collect materials according to the optimal barcode. When the workers collect the materials, they must scan the barcode on the materials with the barcode reader to further confirm whether the collected materials are correct or not. If the barcode of the material received is not consistent with the optimal barcode, an alarm will appear. The information of the materials received by the workers will be uploaded to the computer management system and stored in the database for the administrators to query. In the warehouse management, it also has the functions of manually clearing the optimal barcode information on the site and real-time displaying the working status on the site.

2.4 System Management

The main functions of the system measurement module are as follows.

1)Permission management: Realize assigning user name by role and assigning user permission by business.

2) Password management: set initial passwords for all users.

3) Barcode Management: When a certain material is exhausted, the system will automatically delete the corresponding barcode of that material and automatically update the optimal barcode number of that type of material. The system administrator can also delete the barcode information manually according to the actual situation.

2.5 Database Management

Any material has a unique barcode label, and the information of its incoming, outgoing and every refilling is stored in the database of the upper computer. Through the management software, the administrator can query the material by conditions (such as barcode, material name, operation time, operator); can easily view a material from the incoming stock to the collaterals out of the warehouse, as well as the use of the complete process of consumption; but also can view the current balance of the material.

SOL Access Manager is used to establish the connection between database columns and Configuration King variables, including the establishment of form templates and records of the two parts of the function. Through the form template, you can create a table in the database table; through the record body, you can establish the database table columns and the link between the configuration king, allowing the configuration king through the record body to directly manipulate the data in the database.

1) Create ACCESS database.

This system has the following functions: selecting the optimal barcode, viewing the material balance and querying the refill records. First of all, create an empty database named "mydata.accdb", and establish three tables tableonetabletwotablethree in "mydata.accdb".

2) Establish ODBC data source.

Open the ODBC Data Source Manager in the "Control Panel", select the "User DSN" tab, set the data source name to "mine" and select the database. "mydata.accdb", you can complete the data source configuration.

3) Create form template and record body.

Create table templates named "tableone", "tabletwo", "tablethree" and table templates named "bind1", "bind2", "bind3" and "bind4" in Configuration King Project Explorer. "bind1", "bind2", "bind3", "bind11", "bind21", "bind22".

The form template and the record body correspond to which "bind11" is used to update the material balance in real time; "bind22" is used to record the material usage process; "bind3" is used to query the optimal barcode. is used to query the optimal barcode.

3 Touch screen software realization

The model of the touch screen of this system is Milestone MT6103ip, and its monitoring interface is designed by EasyBuilderPro software. This software is a powerful and easy-to-operate human-machine interface design software, which can develop the operation interface. The touch screen interface mainly consists of a power-on interface, a historical data query interface, a system management interface and a dosing control interface. Each interface has screen switching buttons between each other".

1) Start-up interface.

The operator enters into the power-on interface according to his/her work number and password.

2) Historical data query interface.

Administrator can query the complete process of workers' refilling production every day.

3) System management interface.

The administrator can modify the user name and password, correct the system time, pipeline residual liquid, and start and stop the alarm screen.

4) Dosing control interface.

After selecting the type of material to be added, you can enter the dosing control interface. The interface can automatically display the current material name, the optimal bar code and the current quality. In the software design of the touch screen, it is necessary to realize the comparison between the dosing barcode and the optimal barcode through macro instructions. When the workers carry out the feeding operation, they must first use the wireless scanning gun to read the material barcode information. If the material barcode is different from the optimal barcode, an alarm window will appear on the touch screen and cover up the "start charging" button, thus prohibiting the charging production. If the barcode matches, the dosage amount can be set and the solenoid valve can be selected. Finally, click on the "start" button to automatically control the feeding. It can be seen that through the barcode comparison, the unreasonable operation of workers can be avoided.

4Conclusion

Starting from the actual needs of enterprises, on the basis of synthesizing the characteristics of bar code, configuration king, PLC and touch screen technology, this paper is based on the bar code technology of dosage production control and warehouse management system. Through the configuration king software, the development of the warehouse management system; the use of bar code technology, you can automatically select the most priority use of materials; PLC and touch screen, to achieve the automatic and accurate control of the dosage. The system reduces the error rate of manual input and realizes the automation of warehouse management and in/out operation, which provides a guarantee for the traceability of raw materials and also prevents workers from misoperation in the production site and improves the production efficiency. The system has good application prospects and high popularization value.