2020.02.07

2020.02.07Summary:The production tracking system is introduced on the beverage filling line, and each box of beverages has its own "ID card" through coding equipment.The system uses computer numerical control technology and information encryption technology to supervise and manage each product.The application results show that using the production chasing system to improve the beverage production model will significantly improve the quality and credibility of the product, improve the company's production efficiency, and reduce production costs.

1 filling system design

1.1 overall design

Filling system using bar code technology, computer information technology, in the filling line, the box as the smallest unit of information association. In sealing the box, filling system produces a 16-bit anti-tampering code, that is, assigned to each box of drinks an electronic label, so that it has its own "identity card". When the beverage box reaches the corresponding station, the invisible code is sprayed on the box body and the label (including bar code, production date, box code, pallet code and other information) is affixed on the fixed position outside the beverage box. Outside the box labeling information and the box invisible code information is interrelated, the stack information contains the bar code information and invisible code information of all the boxes in the stack.

Through the filling system digital information base, the enterprise ERP system information and the production workshop digital control system information real-time communication, update, so as to realize the error prevention, monitoring, tracking, etc. for each product.

1.2 System production layout and process design

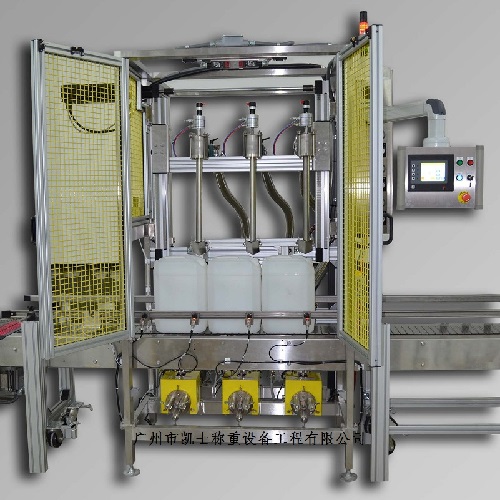

Automatic filling machine is mainly composed of inkjet printer, barcode printer, industrial control machine, filling machinery, the main console and so on.

2 system application results

2.1 Enhance enterprise production efficiency

Filling system in the digital generation module to provide product information, personnel rights and other management content. When the filling workshop classes start production, in the spray code before the authorizer first in the main console of the production line in the system interface to set the production date, product code, workshop, shift and other information (if the staff in the setup of the wrong input or omission of necessary input information, the system will automatically appear to prompt the message), the use of product code automatically generate the corresponding product variety, according to the variety of information, the system corresponds to the boxed Quantity (such as 6 bottles / box, 12 bottles / box, etc.), the control of real-time printing box invisible code, box labeling information, and to ensure that the information is interrelated.

The use of automatic filling machine changed the original cumbersome data entry process, to achieve accurate, timely and rapid data collection. The application of the system improves the production process, strengthens the monitoring of the production site, reduces manual operation, reduces the incidence of human error and improves the production efficiency of the enterprise.

2.2 Increase the difficulty of product anti-counterfeiting

The filling machine generates 16-bit invisible code by utilizing the supporting hardware device, the code generator. This digital information is generated using digital generation system encryption, each box is different, is unique, can not get the key, others can not be deciphered. The outer box label information corresponds to the invisible code of the inner box, so even when the outer box label is destroyed, the system can still recognize the authenticity of the product and quickly check the product name, batch, specification, production plant, production date and other details.

2.3 Reducing Production and Operation Costs

Information technology means that enterprises in the production process to reduce the cost of error correction, the system data by the software to provide automatic backup software for backup, technical information with electronic documents and CD-ROM backup, paperless management, reducing production and operating costs.

2.4 Realize product traceability

Production traceability system information is shared with the enterprise's ERP system information, for quality problems of the product, you can use the filling system to query the product's production, storage, transportation, sales and other related records, using the system's traceability function, to find out who is responsible for the problem, the relevant parties, and timely and accurate to make the appropriate treatment; can also be analyzed through the system data, to be informed of the key reasons affecting product quality, so as to improve the production It can also be analyzed through the system data to know the key reasons affecting product quality, so as to improve the production process and product quality.

Production traceability system information shared with the enterprise's ERP system information, for quality problems of the product, you can use the system to query the product production, storage, transportation, sales and other related records, the use of the filling system's traceability function, to find out who is responsible for the problem, the relevant parties, and timely and accurate to make the appropriate treatment; but also through the analysis of the system data, to be aware of the key reasons affecting product quality, so as to improve the production process and improve product quality. The system can also analyze the data to know the key reasons affecting product quality, so as to improve the production process and product quality.

3 Conclusion

The application of the production traceability system in the beverage filling line has gone through technology introduction, piloting, improvement and promotion, and now it has been fully operated in the company's filling line of many medium and high-grade beverages. After the application of the system in a number of filling workshops, the system is fully in line with the actual beverage production. The use of information technology provides a reliable means for beverage manufacturing to realize refined management. The application of the production traceability system on beverage filling lines improves the overall level of the production site of the filling workshop, enhances the production efficiency of the enterprise, reduces the production cost, improves the quality of beverage products, protects the health of consumers, and increases the confidence of consumers in Gu Yue Long Shan beverages.